1、The three-proof work should be carried out in a separate room, but not completely enclosed, and must have good ventilation facilities.

2、Smoking, drinking food and water are prohibited in the operation room, and alcoholic beverages should not be used before work.

3、Wear a protective apparatus such as a mask or anti-toxic mask, rubber gloves, and chemical protective glasses during operation to avoid injury to your body, which also depends on the three-proof paint product you choose.

4、After work is completed, clean the used equipment in a timely manner, organize and test the tools and equipment, and close the lid of the container containing the three-proof paint.

5、The workplace should be clean and dust-free, and no one should be allowed to enter the workplace.

6、Equipment and tools should be adequately grounded and protected from static electricity.

7、Do not overlap PCBAs during operation; PCBs should be placed horizontally.

8、Before using each batch of raw materials, a small sample curing test (3-5PCS) should be done.

9、Clean and bake the board to remove moisture and water. Dust, moisture and oil must be removed from the surface of the object to be coated so that it can fully utilize its protective effect. Thorough cleaning ensures that corrosive residues are completely removed and that the paint adheres well to the surface of the circuit board. Baking conditions: 60°C, 10-20 minutes, better apply while hot after taking out in the oven;

10、The board should be placed as flat as possible when brushing, there should be no dripping after brushing, the brushing should be flat, and there should be no bare part, between 0.1-0.3mm is appropriate.

11、 Before brushing and spraying, make sure the diluted product is fully stirred and left for 2 hours before brushing or spraying. Use a high quality natural fiber brush and brush lightly at room temperature to apply dip coating. If using a machine, measure the viscosity of the coating (with a viscosity agent or flow cup) and adjust the viscosity with a thinner.

12、The board assembly should be dipped vertically into the paint dip. Unless the connectors are carefully covered, the board should be immersed for 1 minute until the gas disappears and then slowly removed. A uniform film will form on the surface of the board. TFCF has different coating requirements. The board or component should not be dipped too fast to avoid excessive air bubbles.

13、If there is a crust on the surface after dip coating, remove the surface and continue to use.

14、After brushing, place the coating flat on a support frame and prepare for curing. If the surface of the coating is uneven or contains gas, it should be left at room temperature for more time to allow the solvent to flash out before being placed in a high temperature oven for curing.

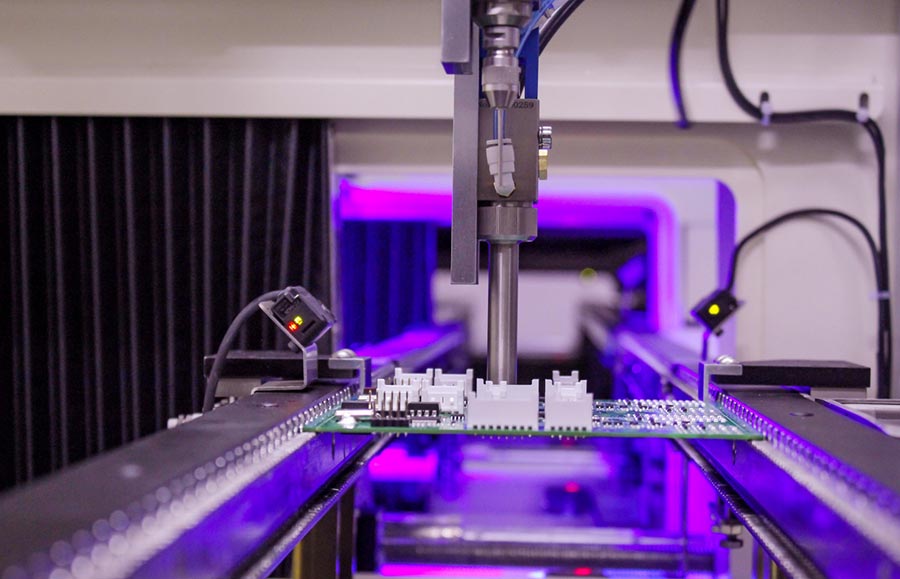

Tortai has a professional automatic spraying line of tri-proof paint with …… advantages, which can provide …… service for customers with high quality requirements.