PCB DESIGN & LAYOUT SERVICES

Printed circuit board assembly (PCBA) design is a key aspect of electronic product development and involves creating functional electronic devices from scratch. PCBA design involves integrating various components on a printed circuit board (PCB) to create functional electronic components. The PCBA design process can be divided into several phases, each requiring careful planning and execution to ensure a successful outcome.

The first step in the PCBA design process is to define concepts and schematics. At this stage, the overall design and intended functionality of the PCBA is established, and a schematic is created to show the connections between the components. The schematic is essentially the blueprint for the PCBA, showing how the various components will be connected and how they will interact to achieve the desired functionality. This phase is critical because it sets the stage for the rest of the PCBA design process.

Once the schematic is complete, the next step is PCB layout design. The third stage of the PCBA design process is component selection. The fourth stage of the PCBA design process is PCB manufacturing. The fifth stage of the PCBA design process is assembly. The final stage of the PCBA design process is testing.

In summary, PCBA design is a complex, multi-stage process that requires careful planning and execution to ensure a successful outcome. The PCBA design process should consider factors such as cost, availability, performance, reliability, EMC, thermal management, and manufacturing constraints to ensure that the final product meets the desired functionality.

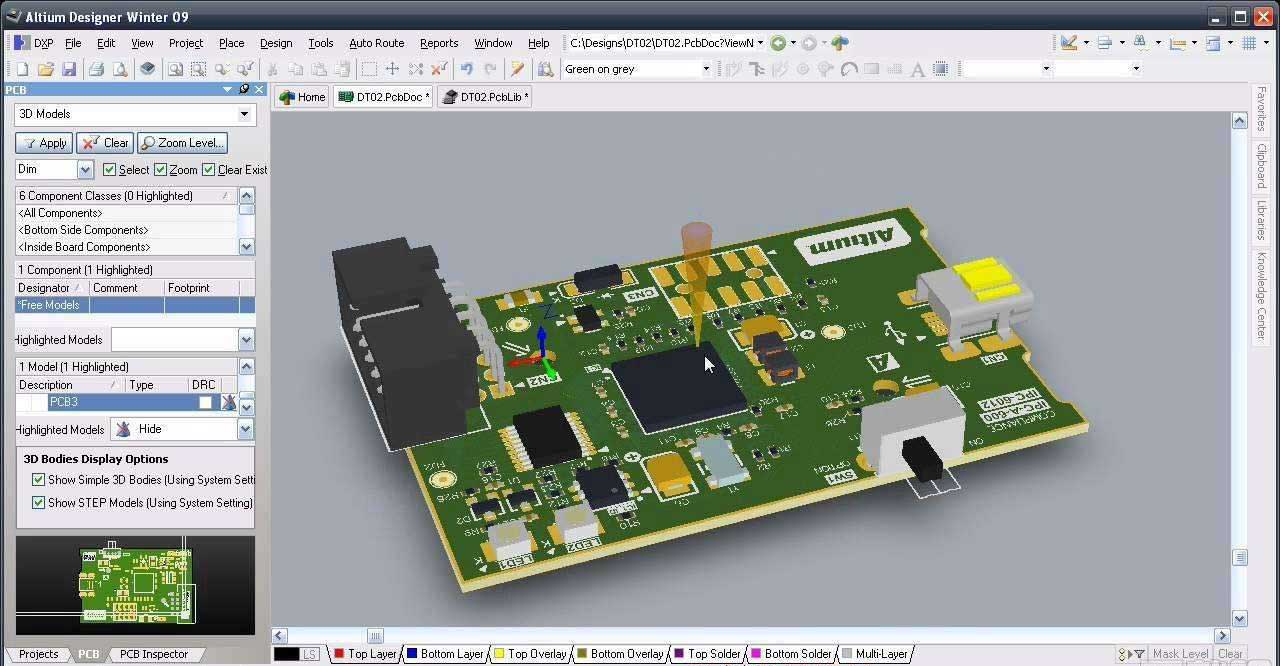

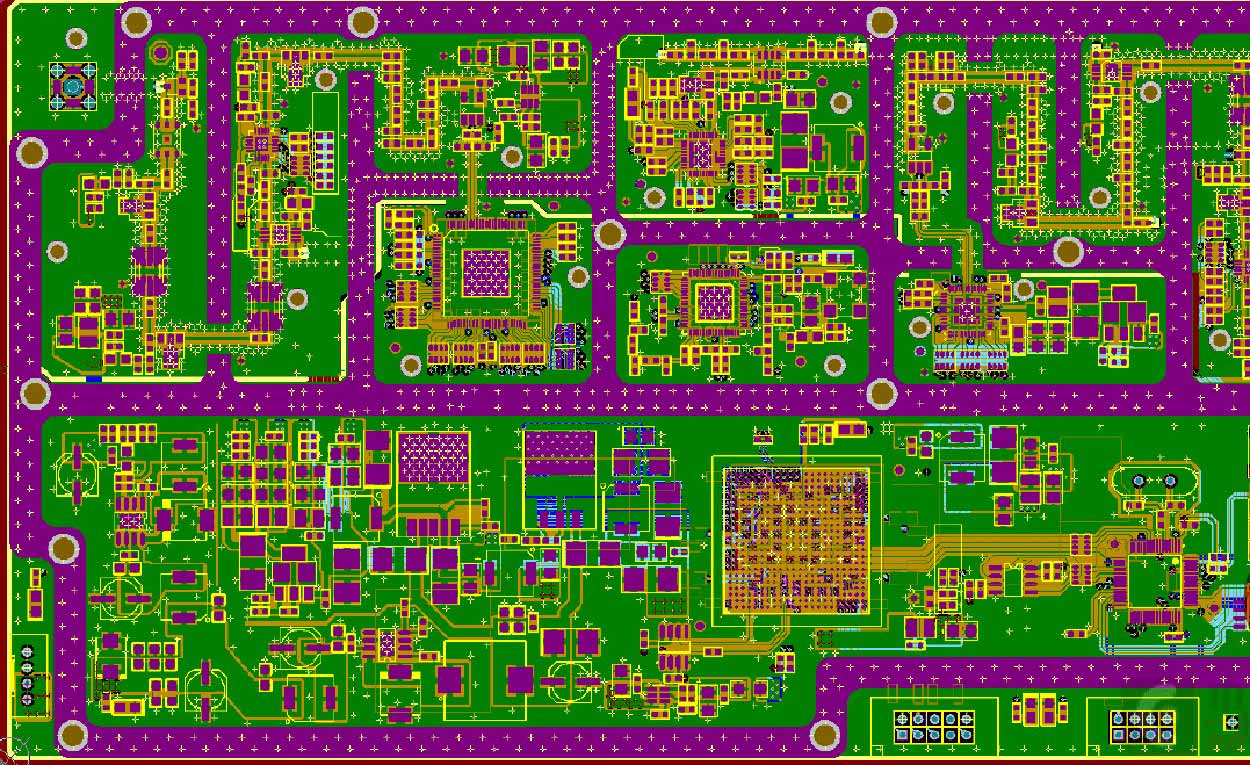

Tortai mainly use Cadence Allegro, Altium Designer, Pads, Protel and other software. We can independently complete PC motherboard, industrial control board, laptop motherboard, medical devices, mobile phones, digital cameras, communication electronics, optical network and other electronic products such as high speed, high density, digital and analog mixed PCB layout design.

Our engineers have an extremely detailed and thorough understanding of multilayer PCB boards, and their understanding of the structure and wiring rules of high-end PCB boards with blind holes and buried holes is even better.

Design Capability:

| Max Signal Design Rate: |

10Gbps CML Differential Signal |

| Max Design Layer: |

40 L |

| Mini line width & distance: |

2.4mil |

| Mini BGA Foot Distance: |

0.4mm |

| Mini hole Diameter: |

6mil |

| Mini laser drilling diameter: |

4mil |

| Max number of Pins: |

63000 |

| Max number of Components: |

3600 |

| Max number of BGA: |

48 |

Bus involved:

I2C bus, SPI bus, CAN bus, ISA bus, EISA bus, VEAS bus, PCI bus, VME bus, VPX bus, RS232 RS485 RS422 bus, USB bus.

High-speed serial bus involved:

PCIE, SIPO, SATA, SAS, SFP, XAUI and other high-speed serial lines, the frequency covers 1.5 GbPs-28 Gbps, signal rate up to 1G-10G.