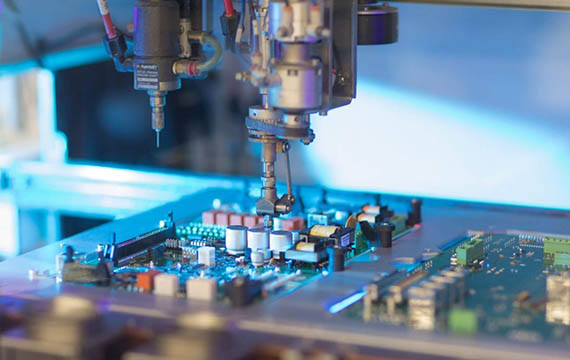

The communications Electronic Manufacturing Services (EMS) market is rapidly expanding due to the growing demand for mobile phones and smart electronic devices. The communications industry plays a key role in facilitating communication and global connectivity.TORTAI, as a specialised electronics assembly manufacturing services provider with a strong engineering team and reliable quality control system, our commitment to stringent quality control ensures that our products meet the highest industry standards. We are constantly optimising our manufacturing processes and technologies to ensure that our customers receive the best possible service and products. We are committed to providing our customers with high quality, high performance electronic products to meet their growing needs.

TORTAI provides DFM reports prior to prototyping, which can help customers avoid glaring errors and reduce NPI time.

We can also help customers design functional test equipment to ensure product quality.

TORTAI can provide test reports on solder reliability, soldering process and product reliability.

Communications Electronics Assembly And Manufacturing Services

|

|

Design & Engineering• Printed Circuit Board Design • BOM Review • Rapid Prototyping |

Electronics Manufacturing• Printed Circuit Board Manufacturing • Printed Circuit Board Assembly • Integrated Manufacturing • Electromechanical assembly |

|

|

Testing and Inspection• Feed Quality Control • AOI Optical Inspection • FAI First Article Inspection • X-ray Inspection • ICT Testing • DIP Insert AOI Test • Aging Test • Functional Test • Electrical Performance Test • FCT Function Test |

Value Added Services• Component Sourcing • Logistics |

Complete Quality Certification System

ISO9001:2015, ISO13485:2016,ISO14001:2015, UL, SGS, RoHS.

Quality and service are the fundamental reasons why medium and large customers have been choosing us for a long time.

Company Overview

| Company Name | Tortai Technologies Co., Ltd. |

| Founded | 2007 |

| Company Size | 4,600 Square Metres of Production Halls |

| Quality Certification | ISO9001 Quality Management System • ISO13485 Medical Device Quality Management System

ISO14001 Environmental Management System |

| Product Certification Scope | UL • RoHS • SGS • REACH |

| Business Scope | PCB Fabrication • Component Purchasing & Inventory Management • SMT SMD Processing • DIP Insertion Soldering • PCBA OEM • Conformal Coating • Electronic Potting • PCBA Testing • Box Build Assembly |

| value-Added Service | NPI New Product Introduction • DFX Analysis • Rapid Prototyping • Programming • SMT Stencils • Fixtures • Repair Service |

| Service Areas | Transportation • Energy • Medical • Security • Communications • AI&IoT |

| Technical Team | Electronics Engineer • BOM Engineer • Structural Engineer • Electronics Procurement Engineer |

| Production Equipment | High Speed YAMAHA SMT Machine • Nitrogen + Vacuum Reflow Oven • 10 Temperature Zones Reflow Oven • Wave Soldering • Three-proof paint automatic spraying line •Precision Potting Machine |

| Testing Equipment | Automatic Material Checker • Solder Paste Inspection (SPI) • Auto Optical Inspection (AOI)for SMT • First Article Inspection (FAI) • X-Ray Testing • In-Circuit Test (ICT) • Function Testing(FCT) • Electric Performance Testing • AOI for DIP • Aging Test |

| SMT lines | 6 assembly lines Automatic Board Loading Machine-DM900, Automatic Printing Machine-GKG Gse, 3DSPI (3D Solder Paste Inspector)-S8030, Yamaha Mounter-YSM10, Yamaha Mounter-YSM20, Nitrogen Vacuum Reflow Soldering Ovens-HX-F1030H, AOI Automatic Optical Inspection-ALD525L. |

| DIP production lines | 2 assembly lines Wave Crest Furnace -350 |

| Three-Proof Paint Spraying Line | 1 assembly line Automatic Coating Machine – iCoat-3, Infrared Curing Furnace (2 m)-iCure-2 |

| Box Build Assembly Line | 2 assembly lines |

| Automatic Precision Potting Machine | 4 table Automatic Glue Filling Machine-XH-001 |

Why Choose TORTAI

|

|

One-Stop PCBA Processing ServiceWe provide customers with a complete supply chain, PCB Manufacturing + Electronic Components Procurement + SMT Mounter + DIP Insertion Soldering + PCBA Testing + Three-Proof Paint Spraying + Electronic Potting Adhesive + Low Voltage Overmoulding Injection + Finished Product Assembly |

Perfect Quality SystemThe company has perfect IS09001, IS013485, ISO14001 and other system certificates, and the products meet the requirements of environmental protection. Strict control and monitoring of each process to ensure high reliability of products |

|

|

FlexibilityIn order to meet the needs of our clients and respond to changes in the external environment, TORTAI from time to time undertakes business process optimisation and changes as required, so that different projects receive services that are appropriate to them and reasonably priced. |

Signed Confidentiality AgreementsTORTAI maintains the highest standards of confidentiality by signing confidentiality agreements with our clients, and all document output must be approved to ensure 100% document non-disclosure. |

Communication PCB Assembly Application Scope:

1、Mobile phones : including motherboards, screen drivers, camera modules, etc.

2、Smart wearable devices: such as smart watches, smart glasses, etc.

3、Drones: including flight control module, camera module, etc.

4、in-vehicle communication devices: e.g. in-vehicle navigation, in-vehicle entertainment system, etc.

5、home smart devices: e.g. smart speakers, smart door locks, etc.

6、Industrial communication devices: e.g. industrial routers, industrial switches, etc.

7、Medical devices: e.g. medical monitors, medical imaging devices, etc.

8、Security devices: e.g. surveillance cameras, intrusion alarm systems, etc.

9、Internet of Things (IoT) equipment: e.g. smart home equipment, smart city equipment, etc.

10、Communication base station equipment: including base station controller, RF module, etc.

11、Wireless communication modules: e.g. Bluetooth modules, Wi-Fi modules, etc.

12、Optical fibre communication equipment: e.g. optical fibre switch, optical fibre transceiver, etc.

13、TV set-top box: including receiver module, decoder module, etc.

14、Voice communication equipment assembly: e.g. voice intercom, voice recognition equipment, etc.

15、Satellite communication equipment: including satellite receivers, satellite transmitters, etc.

Communication PCB Assembly Manufacturing Case