Complete Box Build & Electro-Mechanical Assembly Service

TORTAI is a global electronics manufacturer specialising in electronic box build assembly. We offer a full range of services from small enclosures to larger, more complex box build assemblies, providing box build solutions for complex product system configurations in industrial, medical, transport, new energy, communications, security, and IoT module applications. Our services cover the production, testing and assembly of PCBA circuit boards, HMIs, housings, harness connectors and other modules, ensuring that each component meets strict standards and requirements. Our dedicated team of professionals ensures high quality products and services to meet the needs and expectations of our customers.

TORTAI’s Box Build Assembly Services

We provide the following types of box build assembly services:

- Component Sourcing

- PCB Fabrication

- SMT Stencils

- SMT PCB Assembly

- THT assembly

- Cable and Wire Harness Assembly

- Flexible PCB assembly

- Conformal Coating

- Rework and Modification

- IC Programming & Testing

- Final product assembly

- Packing and delivery

Testing& Inspection Capabilities:

We not only help you assemble PCBs, but also provide testing as a part ofour assembly service. This helps us ensures that the assembled circuit board isfree from any defects. Here are our testing capabilities:

- X-ray Testing: This testing is commonly performed on Quad-flatNo-lead (QFN) PCBs, and Ball Grid Arra ys(BGAs).

- Visual Inspection: As the name implies, visual inspection involves ageneral quality check of the circuit board.

- Functional Testing: In this, we check the functionality of the PCB,and ensure whether the performance is according to the expectations.

- Automated Optical Inspection (AOI): We perform the automated opticalinspection to check whether any components are missing. The solder paste,polarity, and 0201 components are also checked in this inspection.

- In-Circuit Testing (ICT): In-circuit testing is done to checkwhether there are any shorts, or opens in the circuit. Besides this, it alsochecks the capacitance, resistance, and other quantities to ensure that the PCBassembly is done right.

- FAI Testing: first article inspection

Why Choose Us

|

|

|

Box Build AssemblyTORTAI’s box build service will provide you with full support throughout the entire mechanical assembly process from component sourcing, design, manufacturing, testing and repair. We have a dedicated team of specialists who are able to provide responsive and flexible solutions that to meet the specific needs of our customers. Whether it’s small batch production or large scale production, we can meet your needs. Attention to detail and quality control ensures that every component and assembly meets exacting standards and requirements. By choosing Tortai as your box manufacturing partner, you will receive reliable support and quality products. |

Guarantee of High ReliabilityTORTAI’s certifications ensure the high quality of its products and services, with certifications such as ISO9001:2015, ISO13485:2016, ISO14001:2015, SGS, RoHS, and lead-free processes, as and many other certifications such as UL registration and REACH compliant. We always endeavour to provide quality products and services that meet international standards and requirements in order to satisfy our customers’ needs and expectations, and is the basis for Tortai to establish a and long-term partnerships with our customers. |

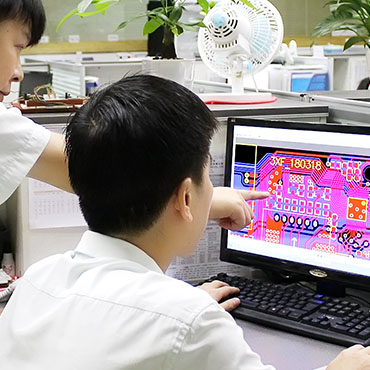

Rich Experience and ExpertiseTORTAI has 16 years of experience in electronic assembly services and our highly trained staff have all the expertise required to ensure products are manufactured to the highest standards. The team is familiar with a wide range of electronic components and assembly processes, all of which follow strict ISO standards and industry requirements. We are committed to providing efficient and reliable electronic assembly services that meet the needs and expectations of our customers. By choosing Tortai as your partner, you will receive professional support and quality electronic assembly products. |

Box Build Case

Over the years, we have been providing one-stop electronic product assembly services to customers in various industries, including: industrial, energy, medical, transportation, communications, home appliances and so on. Here are some of the electronic assembly demonstrations:

Protection and packaging

- Whether it is the material preparation before going online, or the production process and shipment, we attach great importance to product protection to prevent physical damage to products in the turnover and handling process. In the production process, we will adopt anti-static packaging to protect the integrity of the product appearance and avoid some sensitive electronic components from electrostatic damage.

- We will set up a special project leader and project manager to track your electronic products ODM and OEM OEM project throughout the whole process, responsible for the preliminary technical requirements discussion, archiving, mid-term Beta testing, proofing, regression modification, stereotyping, batch and other stage control, and execute according to the expected schedule of the project. To provide you with satisfactory ODM and OEM services for electronic products, strict control of the entire product assembly (Box Building) process quality.

.jpg)