Reverse Engineering Services

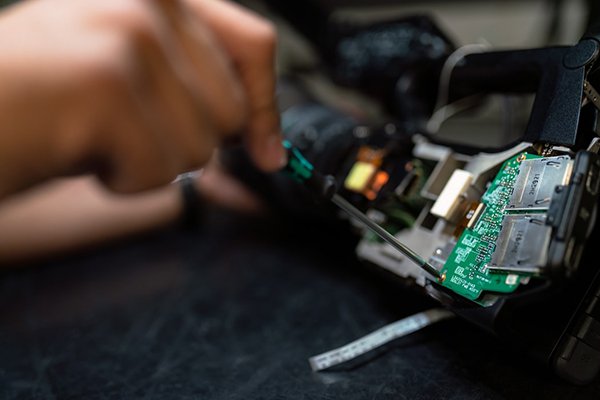

The “Reverse Engineering” is used in many industries, but it is particularly important in the electronics manufacturing industry. Reverse engineering is the process of taking a product apart to understand how it works and then using that knowledge to create a new product or improve existing products.

One of the main reasons for reverse engineering in electronics manufacturing is to create more efficient and cost-effective products. By understanding how an existing product works, engineers can develop better designs and find ways to reduce costs while still achieving desired levels of performance. Reverse engineering also helps manufacturers stay ahead of their competition by finding ways to make their products better than their competitors.

Reverse engineering also allows manufacturers to quickly identify potential problems with their products before they enter the market. By taking different components apart and analyzing them, engineers can detect any flaws that may exist before they become an issue for consumers. This helps ensure that only quality products reach customers, which helps build customer trust in the brand and maintain its reputation as a reliable manufacturer.

In addition, reverse engineering can be used as a way to learn from competitors’ mistakes or successes, allowing companies to avoid making similar mistakes or capitalizing on successful ideas from other brands. This type of research can provide valuable insight into what works best for consumers, so companies can adjust their designs accordingly and remain competitive in the marketplace.

Overall, reverse engineering plays an important role in helping electronics manufacturers produce high-quality products at competitive prices while staying ahead of competition through innovation and research into competitors’ successes or failures.

PCB Reverse Engineering Tools and Capabilities:

PCB copying refers to cloning, prototyping, replacing components, making BOM lists, and exporting schematic diagrams of existing PCB boards.

Tool: Scanner; Software: Protel 99SE · Pads · Auto CAD · Altium Designer

Range of Capability:

• Top number: 20L

• Make PCB file according to the solid board provided by customer

• Blind hole copy board

• Mini line width and line spacing: 3MIL

• Mini aperture: 0.2MM by machine

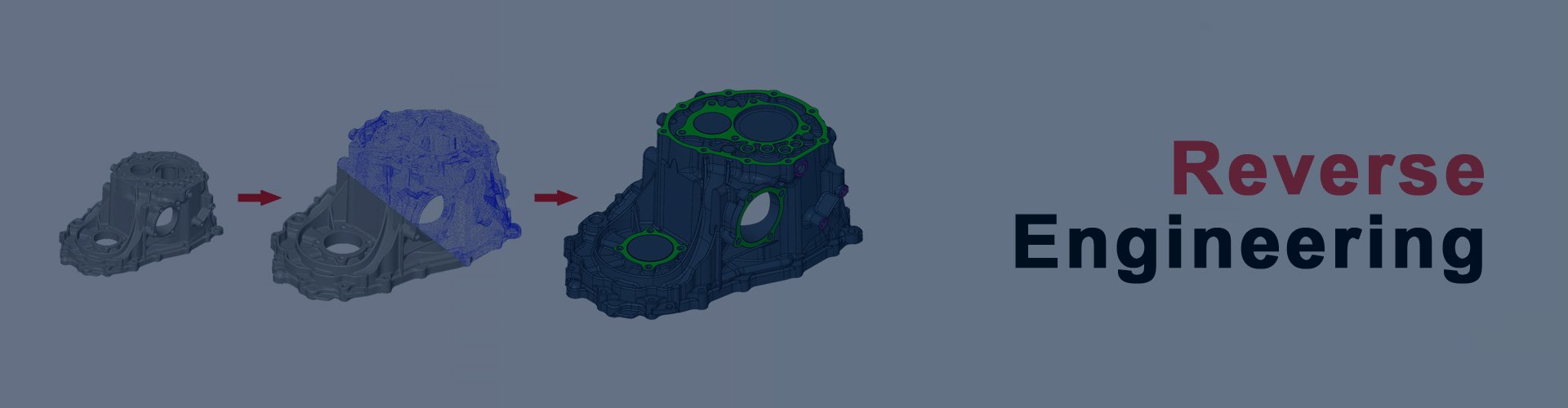

Structural Parts Reverse Engineering Capabilities:

• Reverse Engineering Design: Quickly and accurately draw solid graphics according to the customer template, and track the mold.

• Appearance design: Transform plane ideas into visual product appearance modeling and draw solid graphics.

• Structure design: Design product structure according to customer intent and product function.

• Parting design: According to the 3D drawings provided by the customer and the customer’s requirements to make 3D parting mold.

• Product research and development: According to the customer’s idea to achieve products from creative conception, shape design, 3D structure design.