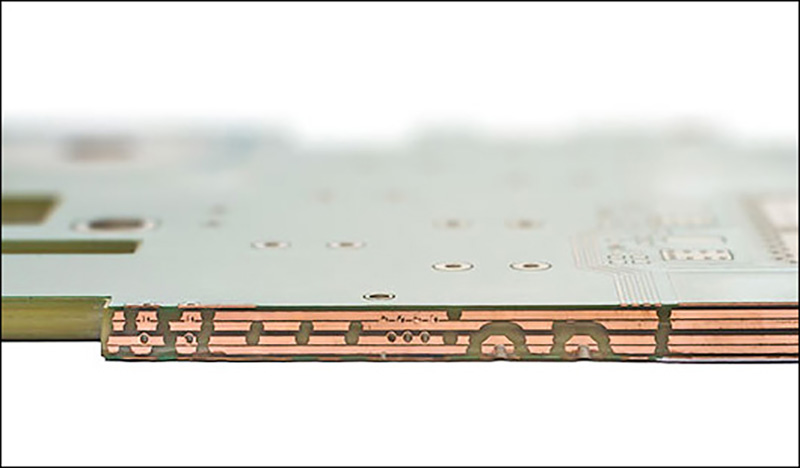

Typically, standard PCBs have a copper thickness of 1oz to 3oz. thick copper PCBs or thick copper PCBs are PCB types with a finished copper weight of more than 4oz (140μm).

What are the uses of thick copper PCBs?

Thick copper PCBs are widely used in power supply systems and power electronics.The extra copper weight in PCBA production allows higher current to be conducted from the board and helps dissipate heat. The most common types of thick copper PCBs are double-sided or multilayer.

Thick copper PCBs are a special type of PCB with different conductive materials, substrate materials, production processes, and applications than conventional PCBs. plating of thick copper circuits allows PCB manufacturers to increase the copper weight in the sidewalls of through-holes and plated holes, which reduces the number of layers and the footprint. Thick copper plating integrates high current and control circuits, allowing for high densities to be achieved through simple board construction.

The construction of thick copper circuits brings the following advantages to pcb:

1、Significantly increased current capacity

2、Higher thermal strain tolerance

3、Better heat dissipation

4、Increased mechanical strength at connectors and PTH holes.

5、Reduced product size

Application of thick copper PCB

With the increase in high power products, the demand for thick copper PCBs has increased significantly. Today’s PCB manufacturers pay more attention to the use of thick copper PCBs to solve the thermal efficiency of high-power electronic products.

Thick copper PCBs are mostly high-current substrates, and high-current PCBs are mainly used for power modules and automotive electronic components. Traditionally, automotive, power supply and power electronics applications used primitive forms of transmission such as cable distribution and sheet metal. Now using thick copper boards instead of transmission forms can not only improve production efficiency and reduce the time cost of wiring, but also increase the reliability of the final product. At the same time, high-current boards can increase the design freedom of the wiring, thus enabling the miniaturisation of the entire product.

In short, heavy copper circuit PCBs play an irreplaceable role in pcb mass production applications have high power, high current and high cooling requirements. Heavy copper PCB manufacturing process and materials have higher requirements than standard PCB. Tortai has advanced equipment and professional engineers to provide customers with high quality thick copper PCB.