Flexible Printed Circuit Board (FPC) after the furnace shrinkage problem is what? How to solve the flexible printed circuit board (FPC) after the furnace shrinkage problem?

Shrinkage can be caused by thermal expansion of the material at high temperature and then shrinkage during cooling. During the overfurnace process, the material used in the FPC undergoes a physical property change under the effect of heat, resulting in a dimensional change of the material. This dimensional change may be temporary, but it can also lead to permanent deformation or damage, especially if the rise and fall is beyond what the material itself can withstand.

Flexible Printed Circuit Board (FPC) rise and shrinkage problems after ovenising can affect the quality and performance of the board, which may lead to connection problems, board distortion or cracking.

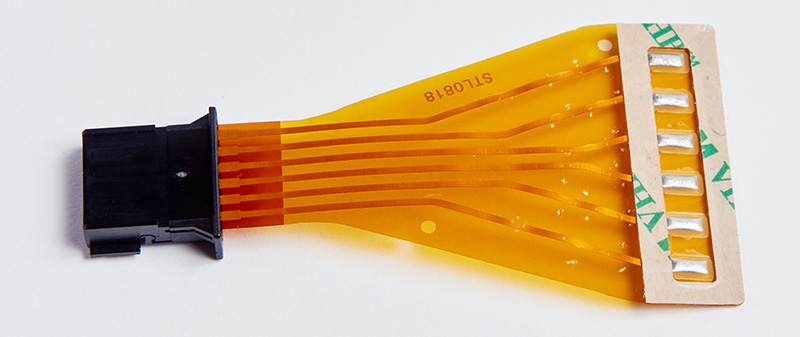

What is a Flexible Printed Circuit Board (FPC)?

FPCs (Flexible Printed Circuit Boards) may undergo shrinkage or lifting after oven processing. This refers to changes in the dimensions of the FPC during the heating and cooling process, and is usually characterised by an increase or decrease in the length, width or thickness of the material.

Flexible PCB (FPC) After The Furnace Shrinkage Will Lead to What?

1、Connection problems: Rising and shrinking may lead to changes in the location of components, circuit traces or solder joints on the FPC, thus affecting the stability and reliability of the connection.

2、Size mismatch: If the Flexible Printed Circuit Board (FPC) is connected to other components or assemblies, the rise and shrinkage may lead to size mismatches, resulting in assembly difficulties or poor joining.

3、Sheet deformation: large-scale expansion and contraction may lead to flexible printed circuit board (FPC) sheet distortion, warping or rupture, affecting the stability and availability of the overall structure.

4、Electrical performance problems: shrinkage may affect the characteristics of the circuit, such as impedance, signal transmission, etc., resulting in electrical instability or failure to meet the design requirements.

5、Reduced reliability: shrinkage makes the physical properties of the FPC change, which may lead to shorten the life of the board or reduce reliability, increasing the risk of failure.

6、Damage or failure: If the rise and shrinkage beyond the material’s tolerance, may lead to FPC internal layer damage, or even permanent deformation or damage.

Why Flexible PCB (FPC) Over The Furnace After The Problem of Shrinkage?

1、The nature of the material: FPC uses a flexible base material (such as polyimide, etc.) in the heat will occur after thermal expansion, as the temperature rises, the material will expand and expand. When cooled, the material contracts. This thermal expansion and cooling contraction leads to changes in the size of the FPC in the oven process.

2、Thermal stresses: Thermal stresses may occur during the oven process, which are caused by uneven temperature distribution or uneven heat transfer. These thermal stresses may lead to deformation of the material, which in turn causes rise and fall problems.

3、Improper control of overfurnace temperature and time: If the overfurnace temperature is too high or the time is too long, it may lead to excessive thermal expansion and contraction of the material in the heat treatment process, thus causing rise and fall problems.

4、Design and structural problems: FPC design may not take into account the coefficient of thermal expansion of the material, or does not provide sufficient structural support to resist the deformation caused by thermal expansion, which may lead to shrinkage and expansion problems after the furnace.

5、Manufacturing process problems: manufacturing process curing is not sufficient, uneven pressure, poor bonding between the layers of materials and other issues, may lead to FPC after the furnace shrinkage. Flexible circuit board processing, FPC, flexible circuit board factory which is good!

Solution

1、Control the oven temperature and time: Optimise the oven temperature and time to ensure that the temperature is evenly distributed and within the allowable material temperature range. Avoid sudden temperature changes or sharp rises and falls in the furnace to reduce thermal stress.

2、Adjust the material formulation: Use more heat-resistant or more stable materials to reduce the phenomenon of rise and fall after the furnace.

3、Optimise printing and manufacturing processes: Ensure that each step in the manufacturing process minimises the effect of thermal stress on the material. This may include optimisation of the printing, baking, curing and over-ovening steps.

4、Use of lower coefficient of thermal expansion materials: The coefficient of thermal expansion of a material affects the rise and fall of the material after oven exposure, and choosing materials with a lower coefficient of thermal expansion may help to minimise rise and fall problems.

5、Increase support and constraints: In the design process to take into account the material in the furnace after the rise and shrinkage, you can add support structures in the design of the plate or the use of constraints in the design to reduce the impact of the rise and shrinkage.

6、Simulation and testing: Use simulation software or carry out actual tests to assess the impact of different parameters and solutions on the shrinkage problem and find the most suitable solution.

7、Continuous improvement and optimisation: shrinkage problems may be affected by a variety of factors, the need for continuous improvement and optimisation of the manufacturing process, material selection and design to reduce the risk of shrinkage.

In solving the problem of shrinkage after FPC over the furnace, it is necessary to take into account a number of factors such as material properties, manufacturing process and design, and may need to continue to try and adjust to find the best solution. It is recommended to co-operate with experts or engineers in related fields to solve the shrinkage problem.