In the field of electronics manufacturing, PCBA (Printed Circuit Board Assembly) plays a crucial role. It involves not only the process of mounting electronic components onto printed circuit boards but also directly impacts the performance, reliability, and cost of the final product. Therefore, understanding PCBA and its quotation process is essential for the success of any project involving electronic components. This article will delve into the fundamentals of PCBA project quotation, including the definition of PCBA, the process flow, and the importance of the quotation process.

Part One: Fundamentals of PCBA Project Quotation

Understanding PCBA

Definition and Role of PCBA in Electronic

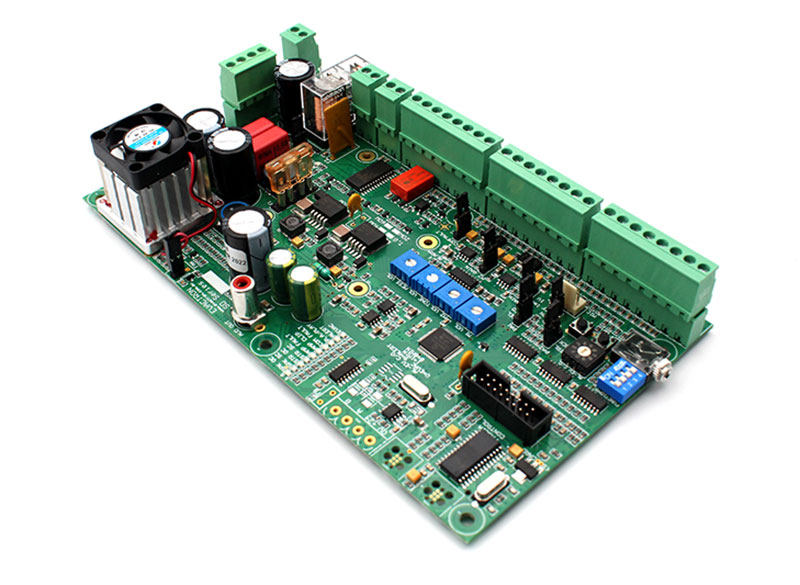

Manufacturing PCBA, or Printed Circuit Board Assembly, is the process of fixing electronic components onto a printed circuit board (PCB) through soldering or other methods and achieving circuit functionality through electrical connections. This process requires precise component placement and soldering techniques, as well as consideration of electrical performance and signal integrity during design and assembly. PCBA is one of the critical steps in electronic manufacturing, directly determining the functionality and performance of electronic products.

Overview of Major PCBA Process Flows

The PCBA process typically includes key steps such as component procurement, PCB manufacturing, component mounting, soldering, testing, and inspection. Component mounting can utilize Surface Mount Technology (SMT) or Through-Hole Technology (THT). Soldering processes may involve techniques like wave soldering, reflow soldering, among others. Each step requires precise control and high-quality execution to ensure the quality and performance of PCBA.

Importance of the Quotation Process

Impact of Quotation on Project Success

In PCBA projects, the quotation process is one of the critical factors determining whether the project can proceed smoothly. An accurate and reasonable quotation not only ensures that the project is implemented within budget but also helps clients and manufacturers effectively control costs and avoid unnecessary resource waste. Additionally, accurate quotations are crucial for gaining client trust and orders, which are essential for building long-term cooperative relationships.

Benefits to Clients and Manufacturers from Accurate Quotations

For clients, accurate quotations mean they can clearly understand project costs, make wiser decisions, optimize product design, and reduce unnecessary expenses. For manufacturers, accurate quotations can increase the success rate of quotations, avoid the risk of cost overruns during project execution, thus ensuring profitability. Furthermore, accurate quotations help enhance the competitiveness of manufacturers and attract more customers.

In conclusion, understanding PCBA and mastering the skills of accurate quotation are crucial for the success of electronic manufacturing projects. A scientific and reasonable quotation process not only ensures the smooth progress of projects but also establishes trust and long-term cooperation between clients and manufacturers. In the following sections, we will further explore the key considerations in the quotation process and how to formulate quotations that are both accurate and competitive.

Part Two: Key Considerations in the Quotation Process

Specific Requirements from Clients on Processes

Different Welding Technologies and Their Cost Implications

Clients may specify specific welding technologies based on product applications and performance requirements, such as traditional wave soldering, more precise reflow soldering, or manual soldering for large components. Different welding technologies correspond to different equipment and process costs, directly affecting the quotation for the entire project.

Selection of Board Materials and Surface Treatment Methods

The type of PCB material (such as FR4, aluminum-based, ceramic-based, etc.) and surface treatment methods (such as HASL, ENIG, OSP, etc.) also affect costs. High-performance board materials and surface treatment methods generally incur higher costs but can provide better electrical performance and reliability.

Specifications, Models, and Brands of Electronic Components

Importance of Bill of Materials (BOM)

The Bill of Materials (BOM) details all the components and their specifications required for the project. The accuracy of the BOM directly affects the accuracy of the quotation, and any omissions or errors may lead to cost increases.

Handling High-Cost or Hard-to-Obtain Components

For high-cost or scarce components in the market, manufacturers need to consider factors such as procurement costs, feasibility of substitutes, and possible delivery delays, all of which need to be reflected in the quotation.

Feasibility of Alternative Models or Solutions

Criteria for Selecting Substitute Components

In cases of component shortages or high costs, selecting suitable substitute components is an effective solution. The selection of substitute components needs to consider factors such as performance, size, compatibility, etc., to ensure that the final product’s performance is not compromised.

Impact of Alternative Solutions on Project Timelines and Costs

Adopting alternative components or solutions may affect project timelines and costs. In some cases, although alternative solutions may reduce material costs, they may increase the workload for design and testing, thereby affecting overall costs and delivery times.

Optimization of Processes and Solutions

Optimizing Process Flows to Improve Efficiency and Reduce Costs

By optimizing PCBA process flows, such as improving soldering processes and arranging production lines reasonably, production efficiency can be effectively increased, and unnecessary costs can be reduced.

Contribution of Innovative Solutions to Enhancing Product Performance

In some projects, introducing innovative design solutions or technologies may enhance product performance or even reduce costs. This innovation needs to be considered during the quotation process so that clients understand its potential value.

Testing, Inspection, and Certification Requirements

Introduction to Different Testing and Inspection Processes

Depending on product applications and client requirements, functional testing, environmental testing, durability testing, etc., may be required. These testing and inspection processes incur additional costs.

Necessity of Certification for Entry into Specific Markets

For products intended to enter specific markets, specific certifications such as CE certification, FCC certification, etc., may be required. Obtaining these certifications may incur additional costs and time.

Estimated Demand Time and Special Requirements

Impact of Delivery Time on Quotations

Urgent delivery time requirements may lead to increased overtime costs and additional costs for prioritized processing, all of which need to be considered in the quotation.

Consideration of Special Requirements (such as Packaging and Logistics)

Clients may have special packaging and logistics requirements, such as anti-static packaging, specific transportation methods, etc., which also affect the final quotation.

In the quotation process of PCBA projects, considering the above key factors comprehensively is crucial. Accurate quotations not only ensure the smooth progress of projects but also help establish client trust and promote long-term cooperation. In the following sections, we will discuss how to utilize these considerations to formulate quotations that are both accurate and competitive.

Part Three: Steps in Formulating Quotations

Collecting and Analyzing Project Requirements

Communicate with Clients to Clarify Requirements

Successful quoting begins with a thorough understanding of project requirements. This requires in-depth communication with clients to clarify specific requirements, including technical specifications, expected delivery times, testing and certification requirements, etc. This step is the foundation for ensuring the accuracy of quotations.

Importance of Requirement Analysis

Through requirement analysis, key points of the project and potential challenges can be identified. This helps consider all relevant factors during quotation, avoiding unexpected cost increases in the future.

Cost Calculation

Direct and Indirect Costs

Cost calculation is the core of the quotation process. This includes direct costs (such as material costs, labor costs) and indirect costs (such as overhead costs, equipment depreciation). Accurately calculating these costs is crucial for formulating effective quotations.

How to Conduct Cost-Benefit Analysis

Cost-benefit analysis helps manufacturers evaluate the costs and potential benefits of different solutions, thus selecting the most cost-effective solution. This not only helps optimize costs but also enhances the competitiveness of quotations.

Quotation Strategy

Importance of Competitive Quotations

In intense market competition, competitive quotations are key to attracting clients. This requires manufacturers to consider not only costs but also market positioning and the budget of target clients.

Pricing Strategy for Long-term Cooperation

For clients aiming to establish long-term cooperation, manufacturers can consider adopting more flexible pricing strategies, such as providing discounts or favorable conditions, to promote the establishment and maintenance of partnerships.

Preparation of Quotation Documents

Key Information to Include in Quotation Documents

Quotation documents are crucial references for clients to decide whether to accept quotations. Therefore, quotation documents should detail all cost items, explain the basis and conditions of quotations. Additionally, they should include technical specifications of the project, delivery times, and any special requirements.

Clarification of Quotation Terms and Conditions

Quotation documents should also specify the validity period, payment terms, delivery methods, and other terms. This helps avoid misunderstandings and disputes in the future, establishing a clear and reliable basis for cooperation between both parties.

By following the above steps, manufacturers can formulate accurate and competitive quotations for PCBA projects. This not only helps win projects but also promotes long-term cooperation with clients. In the following sections, we will explore how to further improve the accuracy and competitiveness of quotations by optimizing the quotation process and adopting advanced technologies.

Part Four: Case Studies and Best Practices

In the process of quoting PCBA projects, analyzing successful cases and understanding common mistakes can provide valuable experience and lessons, thus improving the accuracy and competitiveness of future projects. Below, we will delve into these aspects.

Analysis of Successful Quotation Cases

Analyzing the Quotation Strategies of Successful Projects

Successful PCBA project quotations often share several common features: accurately understanding client requirements, detailed cost calculations, reasonable profit expectations, and flexible quotation strategies. By analyzing these successful cases, we can find that establishing good communication channels with clients to ensure a thorough understanding of project requirements is key to success. Additionally, adopting advanced cost calculation methods, such as using automated quotation software, can significantly improve the accuracy and efficiency of quotations.

Lessons Learned from Case Studies

Successful cases also teach us that to maintain competitiveness, continuous attention to market dynamics and cost control is necessary. Moreover, flexible quotation strategies, such as providing tailored solutions or additional value-added services, can effectively enhance client satisfaction and loyalty.

Common Mistakes and How to Avoid Them

Common Misconceptions in the Quotation Process

Common mistakes in the PCBA project quotation process include: insufficient understanding of client requirements, underestimation of project costs, overlooking market competition, etc. These errors often lead to overpriced or underpriced quotations, resulting in missed competitive opportunities or profit losses.

Strategies and Recommendations for Avoiding Errors

To avoid these common mistakes, strengthening communication with clients to ensure accurate understanding of project requirements is necessary. Secondly, adopting detailed cost calculation methods considering all possible direct and indirect costs can mitigate the risk of underestimating project costs. Additionally, continuously monitoring market dynamics and understanding competitors’ quotation strategies can help formulate competitive quotations.

By learning from successful cases and avoiding common mistakes, the PCBA project quotation process can be continuously optimized, thereby improving success rates and client satisfaction. In the ever-changing market environment, continuous learning and improvement are key to maintaining competitiveness. By implementing best practices and adopting professional advice, manufacturers can effectively improve the accuracy and efficiency of quotations, winning more projects and gaining client trust.

Conclusion

The Key Role of Quotations in PCBA Project Success

Quotation is not just a number but the starting point of communication between enterprises and clients, serving as a bridge to build trust and understanding. Accurate and competitive quotations ensure the profitability of projects and attract and retain clients. Through effective quotations, enterprises can demonstrate their understanding of project requirements, cost control capabilities, and sensitivity to market dynamics. Therefore, the accuracy, reasonableness, and timeliness of quotations directly affect whether enterprises can win projects and the ultimate success of projects.

The Importance of Continuously Optimizing the Quotation Process

Continuous optimization of the quotation process becomes particularly important with the continuous changes in the market and ongoing technological advancements. This includes not only adopting the latest cost calculation techniques and tools but also continuously adjusting and optimizing quotation strategies to respond to changes in market competition and client demands. By analyzing successful cases and reflecting on errors in the quotation process, enterprises can continuously improve the accuracy and efficiency of quotations, thereby enhancing competitiveness and client satisfaction.

Furthermore, continuous optimization of the quotation process also means strengthening communication with clients and thoroughly understanding their needs and expectations. This helps enterprises customize quotations more effectively, providing more attractive and valuable solutions, thus establishing and maintaining long-term client relationships.

In summary, quotation is a key factor in the success of PCBA projects, and continuous optimization of the quotation process is an important strategy to ensure enterprises maintain an advantage in the competitive market. Through continuous learning, improvement, and innovation, enterprises can improve the accuracy and competitiveness of quotations, win more projects, and achieve sustainable development.