Many engineers, especially those just starting out, ask, “Where can I find the cheapest PCB assembly service? “or” How can I reduce PCB assembly costs? ” For those who only pursue low prices and ignore PCB assembly quality, their project is likely to fail due to low quality boards.

While PCB assemblers have been trying to find ways to lower board assembly costs to attract more business and ultimately more profit, prices vary from assembler to assembler. We strongly recommend balancing assembly quality, customer service and cost. Priority is given to adjusting the circuit design to reduce assembly costs and determine the best overall service for the appropriate PCB component partner within the budget.

Here are 6 tips for you to use to ensure high quality and lower PCB assembly costs.

- Find a reliable, professional, “low cost” PCB component manufacturer.

Almost all PCB assembly service providers claim to provide cost-effective services, but not all provide what they claim. First, you should fully understand the project’s requirements and budget; then research each editor from head to toe via the Internet, magazines or trade shows. It takes a lot of time and effort, but it’s worth it in the long run.” When researching PCB assembly manufacturers, be sure to cover the following areas:

Certificate: The certificate can accurately ensure the PCB assembler’s manufacturing capability and management regulations. Required certifications include ISO9001, RoHS, UL, etc. ISO001 is a set of international quality management standards and guidelines designed to promote the ability of companies and organizations to meet and exceed customer needs and expectations by effectively and efficiently improving quality. Their products and services. Restriction of Hazardous Substances, or RoHS, is a series of restrictive laws concerning the application of six hazardous substances in the manufacture of electronic and electrical equipment. UL’s printed circuit board (PCBS) and power supply listing service requires manufacturers to rigorously test their products by following the correct procedures to minimize product hassles.

Equipment: The latest equipment helps to improve efficiency and high quality assembly. With the development and increasing popularity of surface mount technology (SMT), SMT mount equipment is closely related to the high precision placement and high manufacturing speed of components.

Component Procurement: Based on RayMing’s years of experience in the PCB industry, we have noticed that the PCBS manufacturing phase often wastes money and time due to the disjointed relationship between the process stages. To save money and time, we recommend working with a PCB assembler who provides component procurement services. So you can focus entirely on project engineering and let Assembler do what it can to buy cheap but excellent components and put them on your board. We will discuss how to determine whether PCB component manufacturing has competitive component sourcing capabilities.

If the customer wishes to control the cost, RayMing components will follow the Bom List 100% and we will send you some references that we will replace when you confirm.

In addition to these aspects, when choosing a reliable PCB assembler, we should consider quotation rate, lead time, price, manufacturing capacity, minimum order quantity, etc. Some of these aspects are further discussed in the article.

It is worth noting that the world’s electronic circuits are based on a dollar system, resulting in very little fluctuation in costs between the two. Country – Except labour costs, which vary from country to country. As a result, the price advantage of PCBS assembled and manufactured in the United States and Europe is smaller than that of densely populated developing countries such as China.

Because finding the most suitable PCB component manufacturer for your needs is such a complex process, fighting for only one or a few aspects is only one-sided. You should consider them all.

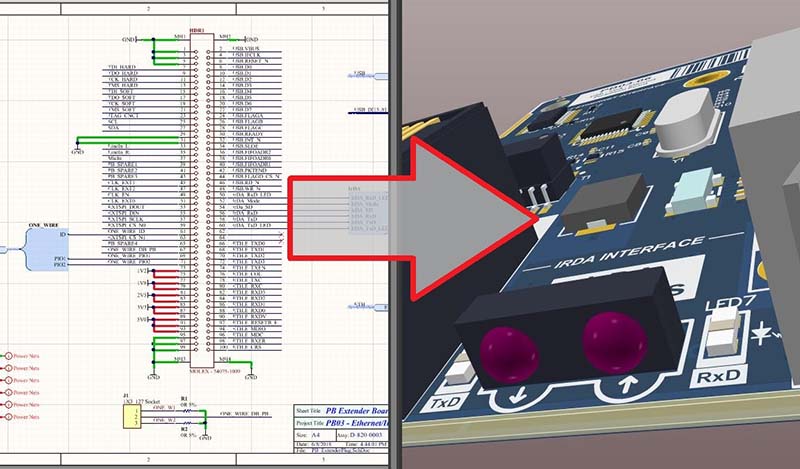

- Schematic design of optimized bare PCB based on low cost problem.

PCB assembly cost

The first step before actual manufacturing is to check that your circuit can be implemented correctly – otherwise known as a manufacturing design (DFM) check. Many PCB assemblers offer a free DFM inspection service that you can rely on to reduce assembly costs.

The figure illustrates the factors that affect the cost of bare PCBS. To reduce the cost of bare PCBS, measurements can be made for each component:

Layers: PCB costs increase as layers are added – in other words, the more layers are added to a board, the higher the cost.

Via technology: Vias, including blind holes, buried holes, and even microholes, play a key role in establishing interconnections on circuit boards. In general, the more holes, the higher the cost, the smaller the diameter, and therefore the more expensive the PCB. Therefore, you should carefully arrange the number of holes to reduce the cost of bare PCBS while ensuring adequate functionality.

Size and shape: The board should be neatly designed and fully functional. The size of the PCB shall conform to the requirements of the pick-up and placing equipment owned by the PCB assembler. It should be designed precisely so that all functions can be achieved and the appropriate amount of space is taken into account. Panels are recommended if necessary. However, with the increasing density and complexity of modern electronic devices, small PCBS can also be relatively complex. Small does not directly lead to low costs. Shape also affects the price of PCBS. Basically, standard shapes like squares or rectangles result in lower prices, while special shapes are usually more expensive.

Finish: Finish helps ensure excellent weldability and electrical properties by preventing pad oxidation. Different types of finishes (HASL, OSP, ENIG, ENEPIG, etc.) each have advantages and disadvantages – choose the type of finish that best suits your product requirements.

As it is, the cost of a bare PCB comes from multiple elements, each of which can cause its final price to fluctuate slightly. Based on our years of PCB manufacturing and assembly experience, these are just some practical tips.

These key factors must be addressed in PCB assembly, all of which can be simplified with the appropriate PCB component manufacturer.

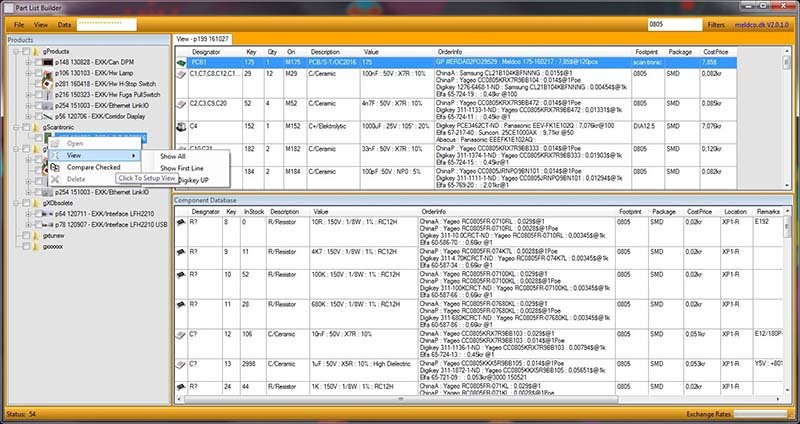

- Prepare a valid and complete BOM.

A bill of materials (BOM) is a comprehensive list of raw materials, materials, and assembly components used in the manufacture of a product. Some people may think that creating a BOM is much easier than creating a Gerber file. In fact, we find that BOM in Gerber files tends to have more errors.

The complete BOM should include the PCB component manufacturer’s basic items, including part number, manufacturer name, reference mark, quantity, description, case/package, SMT method, top/bottom, point/floor area and BOM level. Usually PCB assembly manufacturers have their own internal BOM templates and BOM creation guides that you can fill in accordingly and speed up the quotation process.

You are strongly advised to add replacement components to the BOM. As electronics evolve at an ever faster rate, components are of course rapidly upgraded and old parts are discarded. Although your PCB assembler will inform you of the discontinued product, time is wasted locating the replacement, delaying production. By providing a complete BOM and replacement, the PCB assembler can provide a quote within a day or two and start production upon confirmation. It’s always a good idea to look ahead and be fully prepared for any emergency.

- Make component procurement clear.

If your company is small, it can be difficult to control your budget and project schedule. In this case, it would make more sense to rely on PCB assembly manufacturers. PCB assembly manufacturers are more likely to have a friendly relationship with franchised parts dealers because of their long-term partnership. They can get the parts they need from these dealers at wholesale prices, well below retail prices. To evaluate a PCB assembly manufacturer that actually works with a franchised parts dealer, you can request a purchase invoice from the dealer.

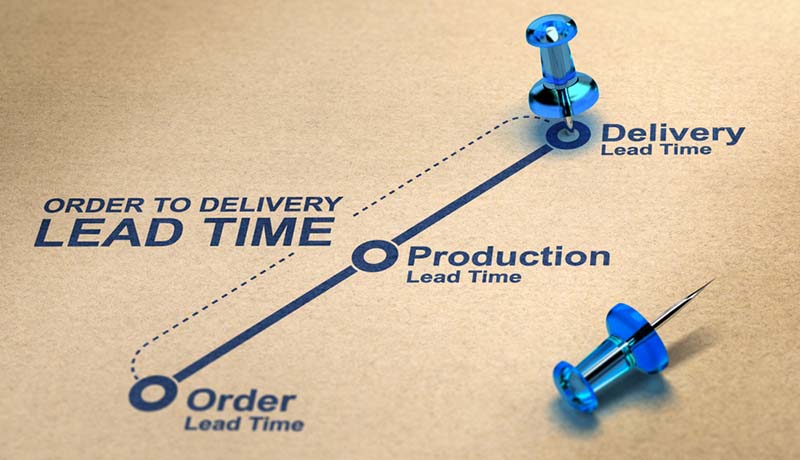

- Adjust order volume and delivery time.

The size of an order is usually inversely proportional to the price of each item. Typically, the larger the order volume, the lower the cost per board component (the same goes for PCB manufacturing services). Consider your company or organization and know your order size (high, medium, or low), then choose a PCB component manufacturer that can meet your order size.

As far as lead time is concerned, the main problem lies in its calculation. Never be fooled by the attractive delivery times promised by PCB component manufacturers. Different PCB assemblers have different lead time calculations, so make sure you know: What is the start time? What are the dates of your order and payment? When will these components arrive? In general, the basic rule of lead time is that the longer lead time, the lower the price.

- Never neglect to check or test.

You must wonder how cost reduction relates to inspection or testing. Often, inspection or testing adds cost. However, under the task theme explained at the beginning of this article, the goal is to reduce costs without compromising product quality.

PCB assembly test

Inspection or testing plays a vital role in promoting high-quality products by clarifying problems or errors in advance. However, some PCB component manufacturers offer such services, while others do not. It is more convenient and efficient to inspect or test products in the homes they are made in. In this case, PCB component manufacturers usually offer lower inspection costs than those that only deal with inspection. Plus, your product doesn’t have to be delivered anywhere.

If your PCB component manufacturer provides inspection services at the end of the production line, you should provide your test fixture so that their tests can be performed according to your specification. Common inspection methods include visual inspection, automatic optical inspection (AOI), and automatic X-ray inspection (AXI). Set up PCB lab and PCBA lab like Rayming to ensure testing and quality.

For large volume orders, the first inspection of the actual batch assembly of the first few products is required. It exposes issues such as component orientation and polarity, and can be modified in a timely manner. If time permits, you can even ask your assembler to provide a sample so you can run it in a practical situation.

One more rule: stick with a PCB component manufacturer as your partner. If you have been doing business with a PCB component manufacturer for more than five years, then you can rely on the smooth cooperation, mutual trust and trust they have built up during that time. But if you’ve been having trouble working with PCB assemblers lately, or your business is suffering from some kind of cost crisis, it’s time to make some changes.

Strict adherence to the rules of thumb discussed in this article can help you make a decision and ultimately choose a new PCB component manufacturer. And you will certainly cut some costs without sacrificing quality.