As the demands for delivery flexibility and cost control in the electronics manufacturing industry continue to rise, more and more enterprises are choosing to outsource the processing of PCBA to third-party suppliers. However, although outsourcing can bring efficiency advantages, it also comes with many potential risks, such as unstable quality, out-of-control delivery schedules, and information leakage. To truly gain benefits from outsourcing, enterprises need to identify these risks in advance and adopt systematic management and control measures.

Clarify technical standards and unify engineering documents

The complexity of PCBA processing determines that any data error may cause product functional defects or rework costs. Before initiating outsourcing, enterprises should ensure the completeness and accuracy of all technical documents:

- BOM, Gerber, coordinate files, assembly drawings should have unified version control;

- Process requirements (such as cleaning, coating, special welding processes) must be clearly marked;

- Special test points, functional definitions, and important component information should be supplemented with explanations.

Standardized engineering documents not only reduce the risk of misunderstandings but also provide a basic guarantee for quality consistency among different batches and different suppliers.

Review the capabilities of suppliers and establish a multi-dimensional assessment mechanism.

Selecting the appropriate PCBA processing partner is the first step to avoid risks. When evaluating suppliers, enterprises should consider multiple aspects:

- Whether the production equipment and process capabilities meet the product process requirements;

- Whether a complete quality management system (such as ISO9001, IATF16949, etc.) is in place;

- Whether a professional engineering support team is equipped;

- Whether the customer service response is timely and responsible.

At the same time, through trial production and sample production, etc., gradually verify its stability and compatibility to avoid systematic risks caused by “going all in at once”.

Strengthen the quality control process to ensure stable delivery

Quality risks are one of the most common problems in PCBA processing outsourcing. To prevent defective batches from entering the market, enterprises should jointly establish a complete quality control mechanism with suppliers:

- Require the implementation of first article inspection (FAI) and full-process traceability;

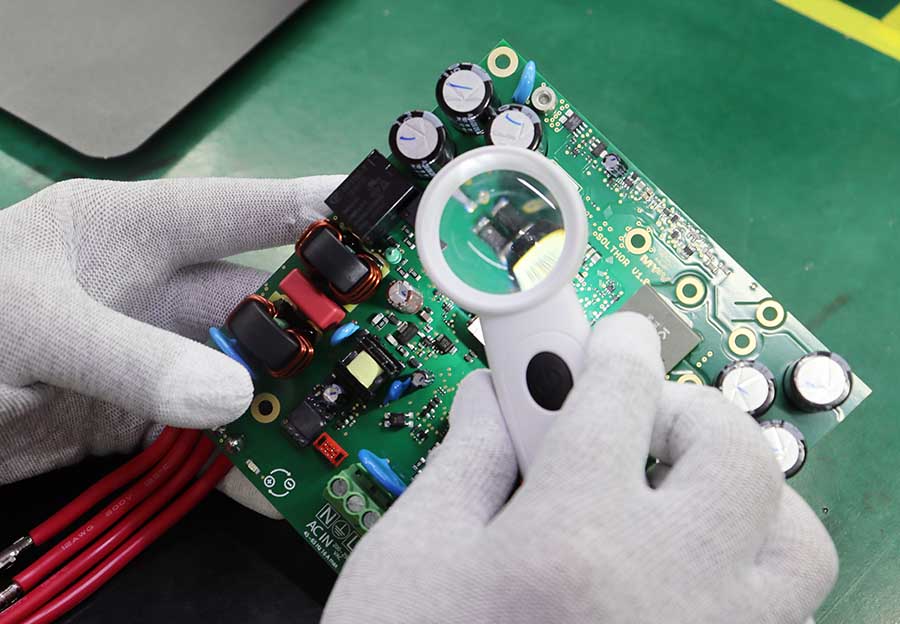

- Clarify the judgment standards for appearance, solder joints, and functional tests;

- Set process control points for key procedures (such as AOI, X-Ray, FCT);

- The shipment must be accompanied by complete inspection reports and quality records.

If necessary, the customer can regularly dispatch QC personnel or third-party institutions for random inspections to enhance risk prevention capabilities.

Standardize communication processes and reduce information errors

In actual cooperation, many problems often arise from inadequate communication or distorted information transmission. Therefore, enterprises should establish an efficient and clear communication mechanism:

- Designate project liaison persons and assign communication responsibilities;

- All changes should be recorded in writing, clearly specifying the version and effective time;

- Important matters should be documented through meeting minutes, email follow-ups, system records, etc. to provide evidence.

Standardized communication not only helps the project proceed smoothly, but also provides a basis for responsibility determination and problem tracing when problems occur.

Strengthen confidentiality management to prevent technology and information leakage.

For projects involving patented designs, core circuits or customized software, information security is a risk point that cannot be ignored. When an enterprise outsources PCB assembly processing, it should take the following measures:

- Sign a confidentiality agreement (NDA) with the supplier;

- Sensitive components, programs or test software can be controlled by the client;

- Set read-only permissions for important data or use encrypted transmission methods;

- Conduct necessary evaluations of the supplier’s information security system.

While protecting its own intellectual property rights, it also enhances the trust foundation with the supplier.

Outsourcing PCB assembly processing is a systematic project, and the risks involved are not uncontrollable. As long as enterprises make proper arrangements in advance in aspects such as supplier selection, technical document management, quality control, communication processes, and information security, and strictly implement them, they can significantly reduce potential problems in outsourcing and truly achieve the dual goals of cost optimization and efficiency improvement. Outsourcing is not about giving up control, but rather about controlling quality and progress in a different way. A cautious and prudent strategy is the key for every enterprise to ensure the successful delivery of PCB assembly processing.