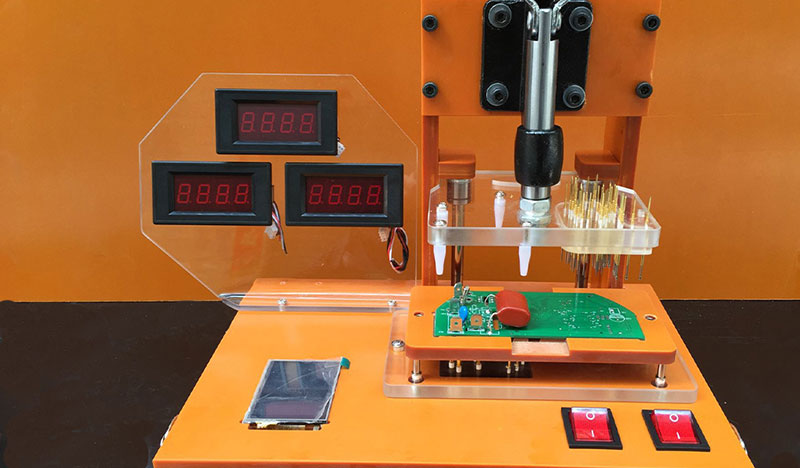

What is PCBA Test Fixture?

PCBA test fixture is a very important equipment in PCBA processing plant, generally placed at the end of the production chain, used to detect whether the product is intact. In the PCBA test fixture production and testing, need to meet the requirements of the regulations in order to improve the accuracy of the test, improve the quality of shipments.

PCBA test fixture is specialised in the function of the product, power calibration, life, performance and other tests, a test fixture. Because it is mainly used in the PCBA production line for product testing of various indicators, so called PCBA test fixture.

Classification of PCBA Test Fixture

1、ICT test mainly contains circuit on-off, voltage and current values and fluctuation curve, amplitude, noise, etc..

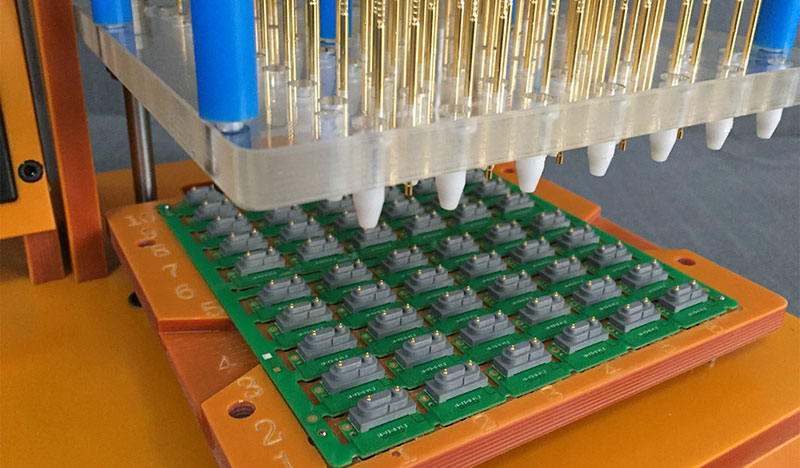

2、FCT test requires IC program burning, simulation test on the function of the whole PCBA board, to find out the problems in hardware and software, and equipped with the necessary production fixtures and test racks.

3, Fatigue test is mainly on the PCBA board sampling, and function of high-frequency, long-time operation, to observe whether the failure, judge the probability of testing failures, so as to provide feedback on the performance of the PCBA board within the electronic product.

4, Harsh environment test is mainly PCBA board exposed to limit values of temperature, humidity, drop, splash, vibration, to obtain a random sample of the test results, so as to infer the reliability of the entire PCBA board batch of products.

5, Aging test is mainly PCBA boards and electronic products for a long time to power, to keep it working and observe whether any failure failure, after aging test of electronic products to batch factory sales.

The Main Points of PCBA Test Fixture Production

1、According to the test requirements and test panels, select a good control mode can be designed after the structure of the jig, you can design the carrier plate, pressure plate, connector module, etc., jig carrier/pressure plate to avoid a reasonable position, in the product testing has the corresponding protective measures to avoid damage to the test board.

2、The positioning of the jig is accurate, the connector docking should be smooth.

3、Fixture box layout is reasonable, wiring and installation control system space is sufficient.

4、Optical fibre / MIC / SPK / SIM card simulation card slot should be reserved, and the location of the quasi-area.

5、The reserved interface position of the fixture should be correct, sufficient and reasonable layout.

6、The jig box body locking should be used bag buckle or pressure buckle and other ways to facilitate the replacement of parts and maintenance.

7、The correct zero calibration. The zero drift of the test fixtures will change with the change of test conditions or test fixtures are different and produce changes, so the zero correction of open circuit and short circuit is very necessary. So FCT test fixtures have open circuit and short circuit correction settings.

8、When the fixtures appear broken needle and aging can be replaced with a needle maintenance to continue to use. If the fixture is damaged and can not be repaired to use and customer change is no longer used, need to be re-made.

PCBA test fixtures are generally customised for a particular product fixtures, can effectively improve productivity and shipment quality.

PCBA Test Fixture Production Process

1、The test should be based on the product under test and customer test requirements, select the final fixture control mode design, design of the pressure plate, carrier plate and other modules.

2、Fixture pressure plate or carrier plate in the design of the position must be accurate, can not let the product in the test when the test board pressure bad.

3、The positioning of the test fixture should be accurate, the connector docking should be smooth.

4、Test fixtures will have a certain design of a box, put the test product inside, in the design of the fixture must maintain the box of sufficient space, the layout of the box must be reasonable.

5、Test fixtures reserved interface location should be correct, adequate, reasonable layout.

PCBA test fixture production is complete, just put the PCBA board into the test fixture, you can achieve the PCBA board and test fixture positioning, positioning accuracy and test fixture production process has a great relationship.