Nitrogen Vacuum Reflow Soldering

Nitrogen vacuum reflow soldering is a nitrogen-shielded reflow soldering technique performed in a vacuum environment. During the reflow process, the component to be soldered is placed in a vacuum chamber and injected with high purity nitrogen gas in the vacuum environment. Nitrogen helps to exclude oxygen, reducing oxidation and improving the quality of the solder joint. Vacuum nitrogen reflow soldering is suitable for all kinds of high-reliability electronic assemblies, but the running cost is higher than normal reflow soldering.TORTAI is the first manufacturer to use nitrogen vacuum reflow soldering equipments in the same scale of PCB assembly factories, which is suitable for the fields of semiconductors, aerospace, national defence and military industry, medical care, automotive electronics, 5G communication, LED and other areas of high-precision and ultra-high requirements; high-efficiency heating, precise control, adopting the Patented structure and heating technology, heating up to 350 ℃, temperature control accuracy ± 1 ℃, effectively solve the problem of suppressing the void rate in the welding of high-end products.

PCB board: aluminium substrate, copper substrate, flexible and hard combination board, FPC soft board.

PCB layers: 10 layers, 20 layers, 36 layers of difficult control boards, highly complex module boards.

Device-related: BGA, QFN, AQFN, IBGT, modules, modules, POP special areas of various high-power devices and modules.

Industry: aerospace, military, automotive electronics, rail transit, artificial intelligence, 5G communications, medical, semiconductor, special lighting, digital currency, special servers, and so on.

Bubble cavity rate: vacuum reflow soldering can be controlled at 1% 1.5% 2%, (ordinary reflow soldering about 20%).

High reliability of products: safe and reliable products, reliable use, reliable end products, reliable production process, reliable production process, reliable production yield.

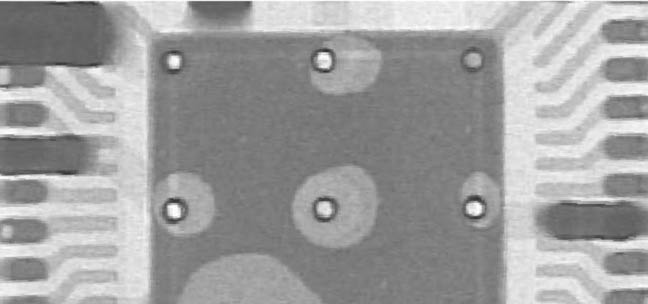

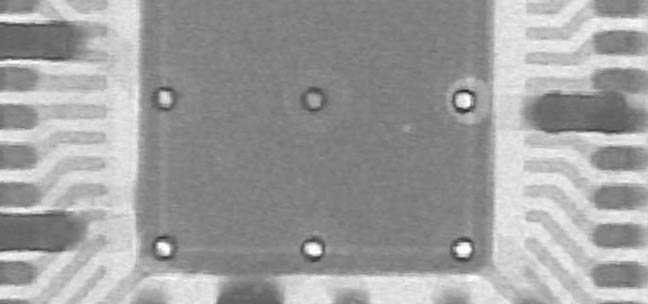

Comparison of The Effect of Vacuum Reflow Soldering

|

|

| Ordinary reflow soldering

The incidence of welding bubbles under normal atmospheric pressure is about 25%. |

Vacuum reflow soldering

Soldering in vacuum air pressure, the incidence of bubbles in 1%-5% or even up to 0.5% or so. |

Application Scenario

|

|

|

| Aerospace | Rail Traffic | Medical |

|

|

|

| Artificial Intelligence | 5G Communication | Transportation |