On 31 December 2025, Tortai Technologies‘ Quality Department convened all Production Department colleagues in the Quality Department conference room for the ‘2025 Electronic Assembly Manufacturing Process Quality Review Meeting’. Centred on ‘reviewing issues and anchoring improvements’, the session systematically addressed annual process pain points and collaboratively mapped out quality enhancement pathways for 2026.

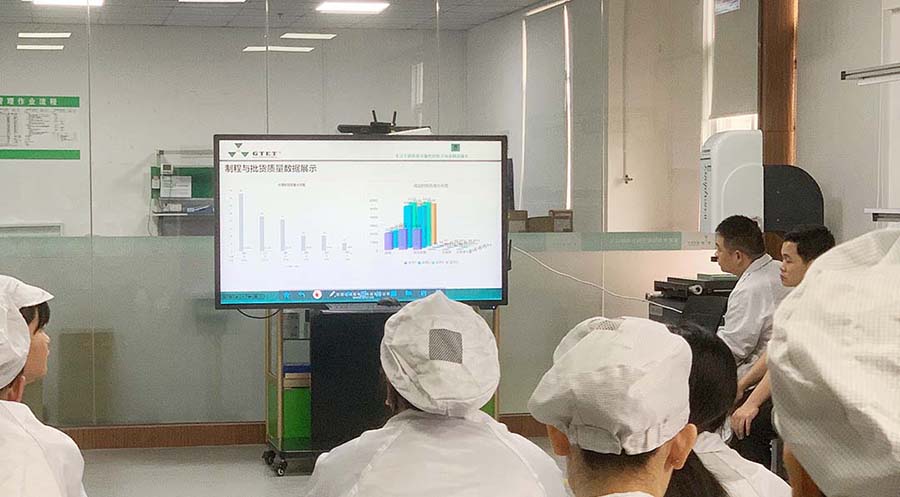

During the meeting, the Quality Department first presented a comprehensive overview of 2025’s electronic assembly quality performance through data dashboards and case studies: the annual process defect rate decreased by 8% year-on-year. However, detailed analysis revealed that issues such as solder joint defects, component placement misalignment, and electrostatic discharge (ESD) protection oversights still accounted for 30% of customer complaints. Recurring problems persisted in certain processes due to deviations in operational standard implementation. Addressing these persistent challenges, the Quality Department collaborated with Production Department specialists to deconstruct root causes: inherent weaknesses included insufficient equipment parameter calibration frequency, while soft vulnerabilities exposed inadequate new employee training coverage. Crucially, cross-departmental coordination efficiency was identified as a critical shortfall requiring enhancement.

Working from a problem list, both departments collaborated on-site to develop solutions: Production proposed visualising key process SOPs (Standard Operating Procedures) on wall displays and introducing a ‘dual-position mutual inspection’ mechanism; The Quality Department plans to complete an upgrade of the intelligent monitoring system for all production line equipment by Q1 2026, enabling real-time alerts for parameter anomalies. To address personnel skills, both departments will jointly launch a ‘Monthly Quality Champion’ selection programme and customised training to reinforce the company-wide awareness that ‘quality is manufactured’. The Production Department head stated: Over the past year, we have reaped the benefits of quality improvements. This meeting has further clarified our direction of “addressing issues overnight and ensuring closed-loop improvements”. In 2026, we will strive towards the goal of “zero recurring issues”.”

As a pivotal management initiative concluding the year, this meeting not only provides a clear roadmap for process quality in 2025 but also initiates Gaotuo Electronics’ 2026 ‘Quality Leadership’ strategy through a ‘problem-oriented + collaborative breakthrough’ approach. Moving forward, both departments will deepen their collaboration to make ‘getting it right the first time’ the manufacturing norm, delivering more reliable product capabilities to customers.

Tags: Quality Meeting, Annual Summary