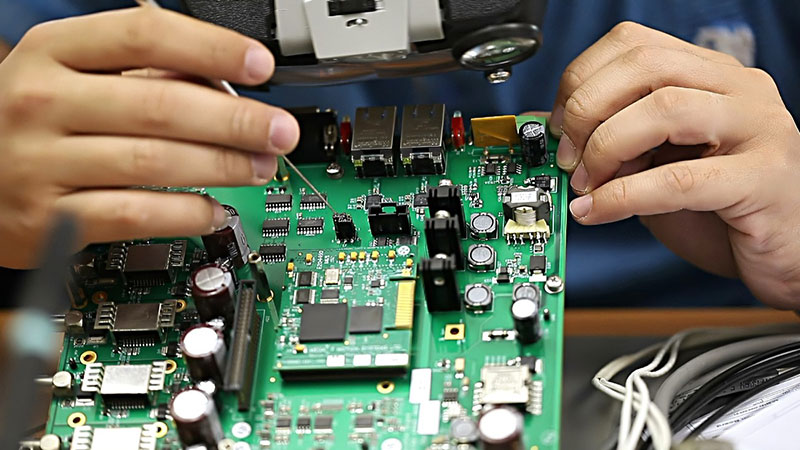

Most PCBA circuit board maintenance has no drawing materials, so many people are skeptical about circuit board maintenance, although various circuit boards vary, but the same is that each circuit board is composed of a variety of integrated blocks, resistors, capacitors and other devices, so the circuit board damage must be one or some of the devices caused by damage. The idea of circuit board maintenance is based on the above factors established. Circuit board maintenance is divided into two parts: inspection and maintenance, in which inspection occupies a very important position. Test the basic knowledge of each device on the circuit board until the bad parts are found and replaced, then a circuit board is repaired.

Circuit board inspection is the process of finding, determining and correcting the fault of each electronic component on the circuit board. In fact, the entire testing process is the thinking process and the testing process of providing logical reasoning clues, so the testing engineer must gradually accumulate experience in the maintenance, testing and overhaul of the circuit board and constantly improve the level.

General electronic equipment is composed of tens of thousands of components, in the maintenance, overhaul, if by direct test and check each component of the PCBA circuit board to find the problem will be very time-consuming, implementation is also very difficult. Then from the fault phenomenon to the cause of the fault, the box-type maintenance method is an important maintenance method. As long as the circuit board detects the problem, it is easy to repair.

An ordinary circuit board, circuit combination into tens of millions, elements often change, character recognition is the key, resistance capacitance is the most common, damage is also very common, resistance resistance value is easy to change, capacitance leakage leakage, inductance transformer is a coil, simple test to see on and off, diode and transistor, the PN junction and anti, MOS tube and thyristor, trigger test is the key, The above are discrete parts, integrated circuits for many years, optocoupler isolation before and after the level, damage that is tens of millions, digital devices are often seen, 40 and 74 marks in front, as well as analog-to-digital converters, it is very difficult to test, don’t forget ROM and CPLD, burn to rely on programming, CPU, MCU, timing judgment logic instrument, a variety of sensors, the damage rate is first.

Let’s take a look at the actual case: Fault characteristics and maintenance of industrial PCBA circuit board capacitor damage.

The failure caused by capacitor damage is the highest in electronic equipment, especially the damage of electrolytic capacitor is the most common.

Capacitor damage is manifested as: 1. Capacity becomes smaller; 2. Complete loss of capacity; 3. Leakage; 4. Short circuit.

The role of capacitor in the circuit is different, and the fault caused by it has its own characteristics. In industrial circuit boards, digital circuits account for the vast majority, capacitors are used for power supply filtering, and less capacitors are used for signal coupling and oscillation circuits. If the electrolytic capacitor used in the switching power supply is damaged, the switching power supply may not vibrate, and there is no voltage output; Or the output voltage filter is not good, the circuit due to voltage instability and logic confusion, as the machine works good or bad or can not open the machine, if the capacitor and between the positive and negative terminals of the digital circuit power supply, the fault performance is the same as above. This is especially obvious on the computer motherboard, many computers with a few years appear sometimes can not open the machine, sometimes can turn on the phenomenon, open the chassis, often can see the phenomenon of electrolytic capacitor bulge, if the capacitor removed to measure the capacity, found that the actual value is much lower.

The life of the capacitor is directly related to the ambient temperature, and the higher the ambient temperature, the shorter the life of the capacitor. This law applies not only to electrolytic capacitors, but also to other capacitors. Therefore, when looking for the fault capacitor, it should focus on checking the capacitor close to the heat source, such as the capacitor near the heat sink and high-power components, the closer it is, the greater the possibility of damage.

Once repaired the power supply of an X-ray flaw detector, the user reflected that there was smoke coming out of the power supply, and after opening the case, it was found that there was a 1000uF/350V large capacitor with something like oil coming out, and a capacity of only dozens of uF was removed, and it was found that only this capacitor was closest to the heat sink of the rectifier bridge, and the others were far away. In addition, there is a short circuit of the ceramic capacitor, and it is also found that the capacitor is relatively close to the heating part. Therefore, it should be focused on the maintenance and search. Some capacitors leak more seriously, and even hot hands when touched with fingers, this capacitor must be replaced. In the maintenance of the good and bad fault, excluding the possibility of poor contact, generally most of the fault caused by capacitor damage. So in the event of such a failure, you can focus on checking the capacitor, and replacing the capacitor is often surprising (of course, you should also pay attention to the quality of the capacitor, and choose a better brand).