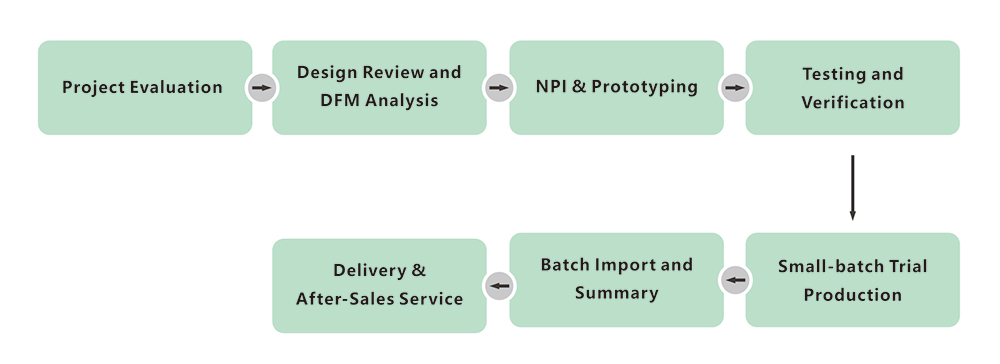

How We Partner with You: The Tortai Technologies End-to-End PCBA Service Process

At Tortai Technologies, we firmly believe that a clear and rigorous process is the cornerstone of exceptional quality. What we offer our global clients is not just PCBA manufacturing, but a full-lifecycle partnership system—from concept to mass production, and from delivery to iteration. The following process is designed to ensure project transparency, smooth communication, manageable risks, and predictable outcomes.

Part 1: Service Process Overview

Our complete end-to-end service comprises four core stages, each with clearly defined deliverables and Service Level Agreements (SLAs).

- Inquiry & Solution Design

- NPI & Prototyping

- Mass Production & Delivery

- Continuous Support & Partnership

Part 2: Detailed Stage Breakdown

Stage 1: Inquiry & Solution Design (1-5 Business Days)

The goal of this stage is to deeply understand your needs and provide you with an optimal, cost-effective manufacturing solution through professional engineering analysis, mitigating risks from the source.

| Step | Key Actions | Deliverables | SLA |

| 1. Inquiry & Analysis | Your dedicated project team (Sales + Engineering) conducts a preliminary review of your RFQ documents (Gerber, BOM, etc.) and establishes a dedicated communication channel with you. | Project initiation assessment, list of any missing documentation. | Respond and form project team within 24 hours. |

| 2. DFM/DFT Assessment | The engineering team performs in-depth Design for Manufacturability (DFM) and Design for Testability (DFT) analysis to identify potential risks in design, process, and supply chain. | A complimentary “Preliminary DFM/DFT Analysis Report,” including a risk checklist and optimization suggestions. | Completed within 3-5 business days. |

| 3. Transparent Quoting | Based on the DFM/DFT results and BOM health analysis, we provide a detailed and transparent engineering quotation, with a clear breakdown of costs for materials, manufacturing, testing, NRE, etc. | Detailed Quotation, including pricing for different volume tiers. | Within 24-72 hours (after DFM completion). |

> Our Value: At the quotation stage, you receive more than just a price list; you get professional design optimization advice from our senior engineers that can save you long-term costs.

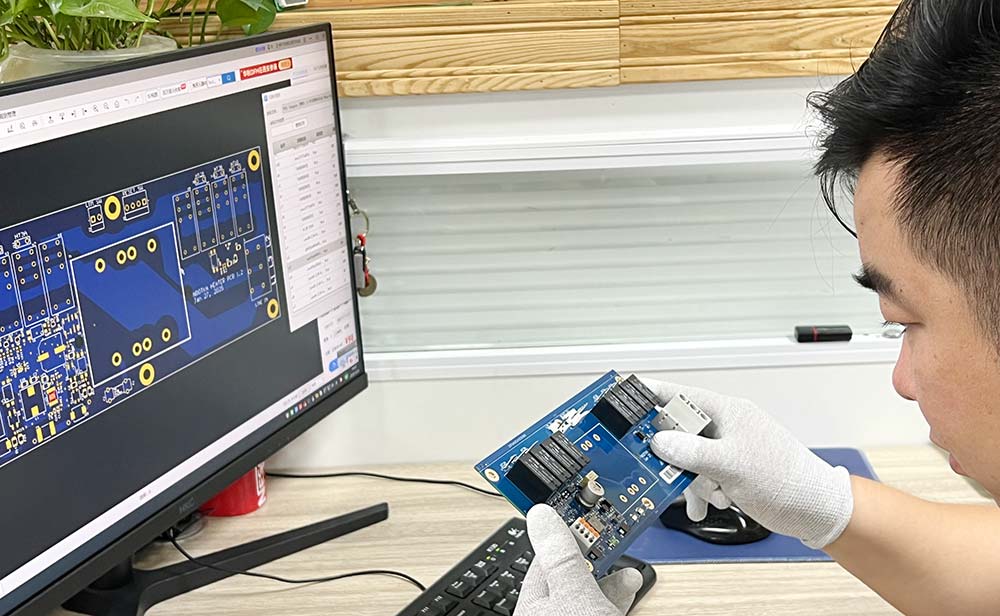

Stage 2: NPI & Prototyping (7-20 Business Days)

The prototype stage is the blueprint for future mass production. It is here that we establish all quality standards, lock in process parameters, and validate the reliability of the supply chain.

| Step | Key Actions | Deliverables | SLA |

| 4. Project Kick-off & Material Prep | A kick-off meeting is held to finalize specifications, Gantt charts, and delivery plans. The procurement team initiates the sourcing of critical components and conducts IQC inspections. | Project Gantt Chart, NRE development plan. | Executed immediately after project launch. |

| 5. Prototype Build & Process Control | The engineering team generates a full production documentation package (SOPs, programs, fixtures). The First Article Inspection (FAI) build is conducted on a dedicated line with full process monitoring (SPI, AOI, X-Ray). | “First Article Inspection (FAI) Report,” production process parameter records. | 5-15 business days (after all materials are ready). |

| 6. Testing, Validation & Reporting | We perform 100% functional testing (FCT), burn-in tests, etc., according to your specifications to ensure the prototype’s functionality and performance are fully compliant. | Fully functional prototypes, a detailed “Prototype Test Report,” and 8D reports for any issues, if required. | 2-5 business days (after prototype build). |

> Our Value: We build prototypes to mass production standards. What you receive is not just a functional prototype, but a “Golden Sample” with stable manufacturing processes and complete quality data.

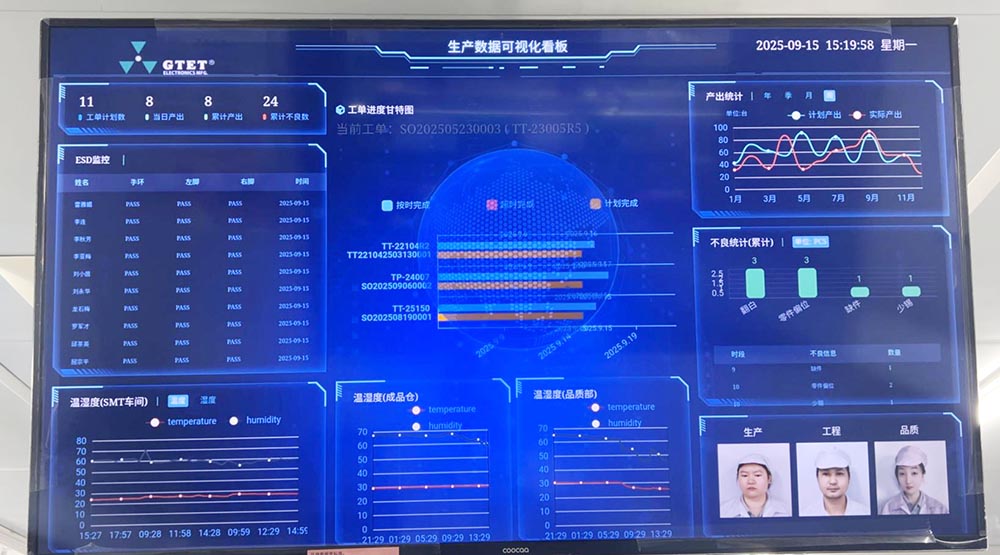

Stage 3: Mass Production & Delivery

The core of this stage is to ensure stable, on-time, and high-quality large-scale delivery through lean production, data-driven quality management, and efficient supply chain coordination.

| Step | Key Actions | Deliverables | SLA |

| 7. Production Planning & SCM | We develop a Master Production Schedule (MPS) based on your forecast and manage material inventory using an MRP system (with support for VMI/safety stock). | Rolling production and delivery schedule. | Executed as per contract. |

| 8. Scaled Production & Quality Monitoring | Mass production is carried out on dedicated lines, with full process traceability managed by our MES. IPQC conducts in-process inspections to ensure production stability. | Traceable production data, stable First Pass Yield (FPY). | Stable output according to schedule. |

| 9. Packaging & Global Logistics | 100% OQC final inspection. Custom anti-static and moisture-proof packaging is used based on product characteristics (e.g., MSL rating). We coordinate global logistics, supporting various trade terms like EXW/FOB/CIF/DDP. | “OQC Inspection Report,” Packing List, and logistics tracking number. | 100% on-time shipment. |

> Our Value: We manage your orders as if they were our own products. Through data-driven lean production, we ensure that every single PCBA delivered to you has consistent, exceptional quality.

Stage 4: Continuous Support & Partnership

Delivery is not the end; it is the beginning of our long-term strategic partnership. We are committed to growing with our clients and continuously creating value.

| Step | Key Actions | Deliverables | SLA |

| 10. After-Sales Support & RMA | We provide a dedicated technical support window to respond quickly to customer feedback and initiate a standardized RMA process for any returns. | RMA analysis reports, problem-solving solutions. | Respond to after-sales issues within 24 hours. |

| 11. Continuous Improvement & Cost-Down | We conduct regular business reviews (QBRs) to analyze quality data, delivery performance, and propose cost-down and efficiency improvement plans for the next phase. | “Quarterly Business Review (QBR) Report,” continuous improvement plans. | Conducted at agreed intervals. |

| 12. Long-Term Strategic Partnership | We proactively provide EOL (End-of-Life) material warnings and offer alternative solutions. We collaborate with you on ECO (Engineering Change Order) management for product upgrades. | EOL risk warning reports, ECO evaluation proposals. | Throughout the entire partnership. |

> Our Value: We are not just looking for one-time orders. We aim to be an extension of your product team—a trustworthy, long-term strategic partner you can grow with.

Part 3: Why Choose the Tortai Technologies Process?

- Risk Mitigation Our powerful DFM/DFT capabilities identify and mitigate manufacturing and testing risks at the design stage, saving you valuable time and costly rework.

- Full Transparency From quotation to delivery, every step and every cost is clearly visible. You will always know the status of your project, with no surprises.

- Built-in Quality We believe that quality is built, not inspected. Our process embeds quality tools like SPC and FMEA into every stage of production.

- Data-Driven All critical process parameters, test data, and traceability information are recorded and analyzed, ensuring that decisions are based on data and that quality is quantifiable and traceable, fully meeting the requirements of high-reliability industries like medical and automotive.

- True Partnership We are more than just a supplier executing orders; we are a strategic partner who provides professional engineering insights, helps you optimize your products, and works with you to tackle market challenges.