— A Practical Case Study of How Professional PCB Manufacturers Tackle Mixed-Process Challenges

Background:

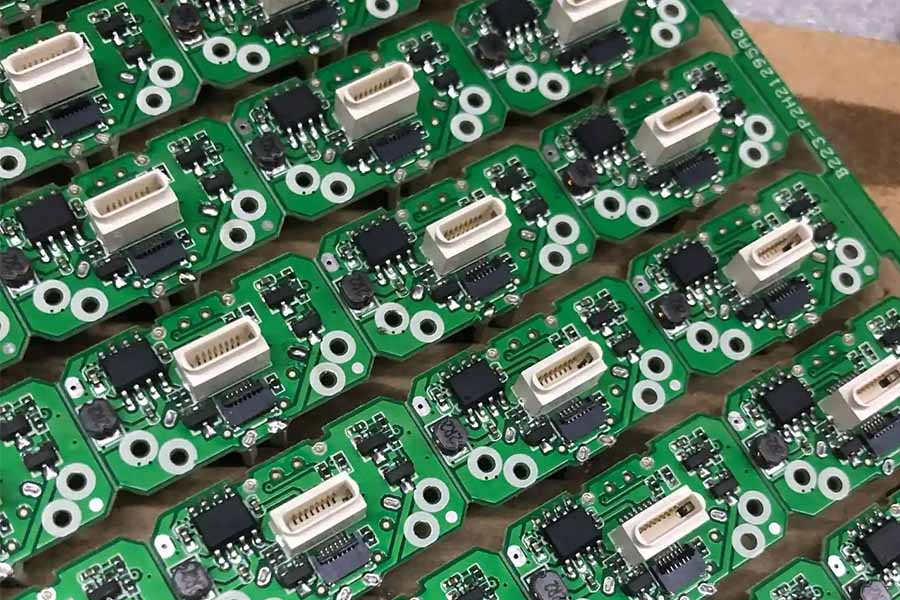

Recently, we encountered a unique case: a long-standing industrial client required several additional components on their existing control board. During incoming material inspection, our engineers discovered the original board utilised leaded processes, whereas our factory operates exclusively with lead-free processes. This seemingly straightforward request actually presented multiple challenges concerning process compatibility, quality control, and compliance management.

1、Problem Identification and Verification

Initial Findings

During an on-site inspection, Engineer Liu noted that the solder joints on the client’s control board exhibited typical leaded solder characteristics—greater lustre and smoother surfaces—through visual examination.

Technical Confirmation

Upon returning to the factory, we promptly engaged in technical discussions with the client, confirming the following key points:

- The client’s original control board indeed utilised Sn63/Pb37 leaded solder (traditional 63/37 tin-lead alloy)

- The client wished for newly added components to maintain consistency with the original process

- The client had specific reasons necessitating continued use of the leaded process (e.g., special application scenarios or legacy system compatibility)

Technical Challenge Analysis

As a modern PCB manufacturer specialising in lead-free processes, we faced the following challenges:

- Process Isolation: Leaded and lead-free solders must never be mixed or cross-contaminated

- Equipment Dedication: Dedicated tools and equipment are required to prevent contamination of the factory’s main production lines

- Training and Conduct Standards: Differences exist in soldering parameters and techniques between leaded and lead-free processes; knowledge of lead hazards, correct use of protective equipment, emergency procedures, and hygiene practices.

- Personnel Protection: Personal Protective Equipment (PPE)

- Quality Standards: Different quality inspection standards must be adopted (e.g., IPC-A-610)

- Environmental compliance: Strict adherence to environmental regulations governing leaded material handling

Solution implementation

Following internal assessment and discussion, we have tailored a professional solution for our client:

(1) Establishing a segregated work area

We have designated a physically isolated dedicated zone within the factory to ensure complete separation between leaded processes and the main factory’s lead-free production lines, including:

- Independent ventilation system

- Clear zoning and signage

- Dedicated workbenches and storage cabinets

(2) Provision of Specialised Equipment and Tools

To prevent cross-contamination, we deployed new, dedicated equipment:

- New soldering irons and temperature control systems

- Specialised fixtures and auxiliary tools

- Leaded solder and flux

- Dedicated cleaning supplies

- Personal Protective Equipment (PPE)

(3)Establishing Rigorous Operating Procedures

We have developed detailed work instructions covering:

- Personnel access protocols for the segregated zone

- Process parameters and requirements for leaded soldering

- Training and conduct standards: with particular emphasis on maintaining correct posture during soldering to minimise facial proximity to solder joints and reduce lead fume inhalation risk.

- Cleaning and management of tools and equipment

- Waste classification and disposal

(4)Quality Control Measures

To ensure final product quality, we implemented multiple inspections:

- Visual inspection of solder joints (based on IPC-A-610 Class 2 standard)

- X-ray inspection to verify internal joint integrity

- Functional testing verification

2、Outcomes and Achievements

Through specialised process segregation and control, we successfully completed modifications to this batch of control boards with specialised requirements for our client, achieving:

(1)Satisfaction of client’s specialised requirements whilst ensuring product quality

(2)Preservation of the factory’s main production line’s lead-free process integrity

(3) Compliant handling of leaded substances in accordance with environmental regulations

(4)Accumulation of valuable experience in managing hybrid processes

3、Industry Background Knowledge Sharing

(1)Differences between leaded and lead-free soldering

| Characteristics | Lead-containing solder (63/37) | Lead-free solder (SAC305) |

| Melting point | 183°C | 217-220°C |

| Moisture retention | fairly good | Relatively poor |

| Appearance of solder joints | Bright and smooth | Slightly dull, with a rather coarse surface |

| Mechanical strength | Medium | Relatively high |

| Thermal fatigue performance | Fairly good | Relatively poor |

| Environmental friendliness | Non-compliant with RoHS | Compliant with RoHS |

(2) Why do certain applications still require leaded processes?

Despite the RoHS Directive driving the electronics manufacturing industry towards lead-free solutions, leaded processes remain permitted or necessary in specific sectors:

- Military and aerospace equipment

- Certain medical devices

- Specific industrial control systems

- Equipment requiring exceptional reliability

- Maintenance and expansion of legacy systems

Conclusion and Insights

This case study demonstrates that within electronics manufacturing, alongside mastering standard processes, the ability to flexibly address specialised requirements and rigorously control process segregation is equally vital. We maintain that true professionalism manifests not only in technical capability but also in the understanding of client needs and the capacity for agile responsiveness.