Introduction: The Dilemma of Model Selection for Low to Mid-Volume PCBA Projects

In the Electronics Manufacturing Services (EMS) field, the two most common cooperation models are Turnkey and Consignment. The former involves the EMS partner managing the entire process from PCB fabrication, component procurement, to assembly and testing; in the latter, the client supplies all or key materials, with the EMS responsible only for the production and processing stages.

According to IDC’s “Electronics Manufacturing Models 2025,” for low to mid-volume projects (≤5000 units/batch), 58% of procurement managers struggle with model selection at the project’s outset because the two models differ significantly in cost structure, supply chain risk, delivery cycle, and quality control.

In China, the “Three-Year Action Plan for High-Quality Development of the Electronics Information Manufacturing Industry (2025–2027)” also mentions optimizing supply chain collaboration models and rationally selecting manufacturing service models based on project characteristics to improve efficiency and reduce risk. For procurement and project managers, understanding the fundamental differences and applicable scenarios of these two models is key to controlling costs and ensuring delivery.

1、Model Definitions and Process Differences

Turnkey

Definition: The EMS partner is responsible for all production resources, including PCB fabrication, component procurement, SMT/DIP assembly, testing, finished product packaging, and logistics. The client only needs to provide design files and requirements specifications.

- Process:Design Files → BOM Verification → Component Procurement → PCB Fabrication → SMT/DIP → ICT/FCT → Finished Product Delivery.

- Characteristics:One-stop delivery, centralized responsibility, supply chain managed by EMS.

Consignment

- Definition:The client provides all or major components and PCBs. The EMS is only responsible for assembly, soldering, testing, and packaging.

- Process:Client Supplies Materials → Incoming Quality Control (IQC) → SMT/DIP → ICT/FCT → Finished Product Delivery.

- Characteristics:The client controls material procurement and cost; EMS responsibility is limited to the manufacturing process.

2、Core Dimension Comparison (Data-Supported)

| Dimension | Turnkey | Consignment | Data/Trend Reference |

| Per-Unit Management Cost | Lower (benefits from bulk purchasing) | Higher (client manages multiple suppliers) | McKinsey “Turnkey vs Consignment Cost Model 2025”: Turnkey saves avg. 12–18% management cost for mid-volume. |

| Procurement Lead Time | EMS centralized procurement, lead time more controllable. | Client self-procurement, susceptible to multiple supplier delays. | Gartner “Supply Chain Lead Time 2025”: Consignment avg. procurement lead time is 15–25% longer than Turnkey. |

| Quality Risk | EMS responsible for the entire chain, easier traceability. | Material quality issues borne by client, split responsibility. | IPC data: Rework rate due to incoming material defects is 2–4 times higher for Consignment. |

| MOQ (Min Order Qty) Limits | Most Turnkey supports no MOQ. | Usually no MOQ limit, but client must stock materials. | Tortai Technologies actual test: Turnkey can achieve 1-unit quick prototyping. |

| Supply Chain Resilience | EMS can flexibly adjust procurement & capacity. | Client must handle material shortages & price fluctuations independently. | EU RoHS 3.0 (2025): Turnkey easier for unified compliance management. |

| Confidentiality & IP Risk | EMS accesses full BOM, requires NDA. | Client can retain privacy for some component procurement. | Industry survey: Turnkey requires stricter contracts & data security measures. |

| Suitable Project Types | New product trial production, fast time-to-market, cross-category projects. | Mature products, high volume, existing stable component supply chain, extreme cost sensitivity. | — |

3、Case Study Comparison: Portable Water Quality Analyzer Project

Background: An environmental tech startup developing a portable water quality analyzer targeting Southeast Asia and the Middle East. First batch planned for 800 units. Project required completion from prototype to delivery within 10 weeks, compliant with CE and RoHS 3.0.

Option A: Turnkey

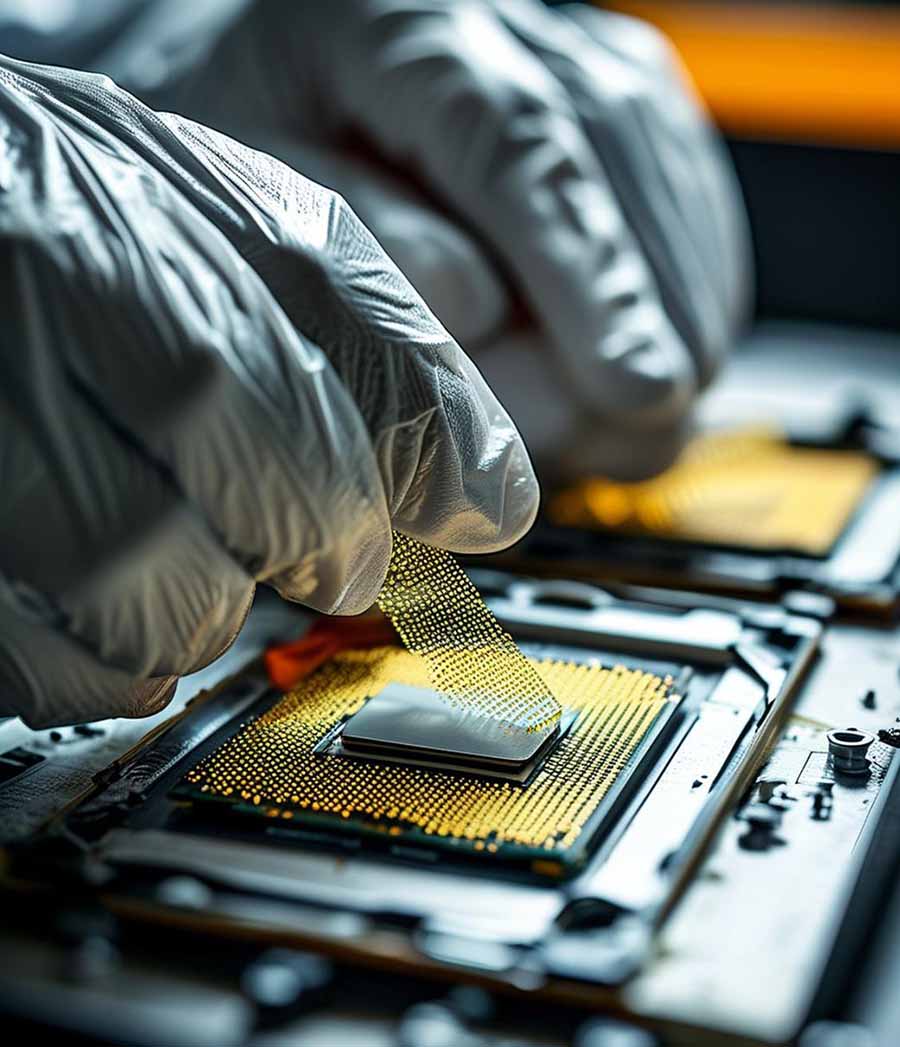

- Execution:Tortai Technologies handled PCB fab, all component procurement, SMT/DIP, ICT/FCT, and conformal coating.

- Procurement Advantage:Core sensors and main control chips procured via EMS long-term agreement pricing, 14% cheaper than client self-procurement, with lead time locked at 3 weeks.

- Timeline:7 weeks from BOM confirmation to first finished batch; second batch delivered 1 week earlier.

- Quality:Integrated incoming inspection and process control; First Pass Yield (FPY) 97.8%, no rework due to material non-conformance.

- Cost Structure:Turnkey unit price includes materials & processing; per-unit management cost 16% lower than self-procurement.

Option B: Consignment

- Execution:Client self-procured all components & PCBs; Tortai Technologies handled only assembly & testing.

- Procurement Challenge:Delays from some sensor suppliers (5 weeks) forced overall production schedule to slip by 3 weeks.

- Quality Risk:A batch of capacitors failed voltage spec, causing 8% product rework. Client bore material and retesting costs.

- Timeline:10 weeks from material readiness to delivery, final shipment delayed by 2 weeks.

- Cost Structure:Although material unit price was slightly lower, actual total per-unit cost was 11% higher than Turnkey due to delays and rework.

- Comparison Conclusion:For this low to mid-volume project, Turnkey outperformed Consignment in delivery time, quality stability, and total cost, proving particularly suitable for new product rapid launch and cross-category material management.

4、Decision Factors for Model Selection

- Supply Chain Control Willingness:Want to control component selection & procurement? → Consignment. Prefer to focus on R&D & marketing? → Turnkey.

- Project Stage & Volume:New product trial, fast iteration, low to mid-volume? → Turnkey is more hassle-free.Mature product, high volume, stable existing supply chain? → Consignment may reduce cost.

- Delivery Time Criticality:Tight deadline? → Turnkey’s centralized procurement and capacity flexibility offer more advantage. Flexible timeline & materials can be stocked early? → Consignment is feasible.

- Quality & Compliance Requirements:Medical, automotive, exports to EU/US under strong regulation? → Turnkey easier for unified compliance & traceability. Internal project or special requirements for component source? → Consignment.

- Cost Structure Sensitivity:Focus only on component unit price? → Consignment might be lower. Consider total cost (incl. management, delays, rework)? → Turnkey is often better.

5、Trends & Policy Impact (2025–2026)

- Environmental Regulations:RoHS 3.0 requires full-chain material compliance; Turnkey mode facilitates unified testing and traceability.

- Supply Chain Security:Amid geopolitical fluctuations, Turnkey’s localized procurement and multi-sourcing strategies can mitigate disruption risks.

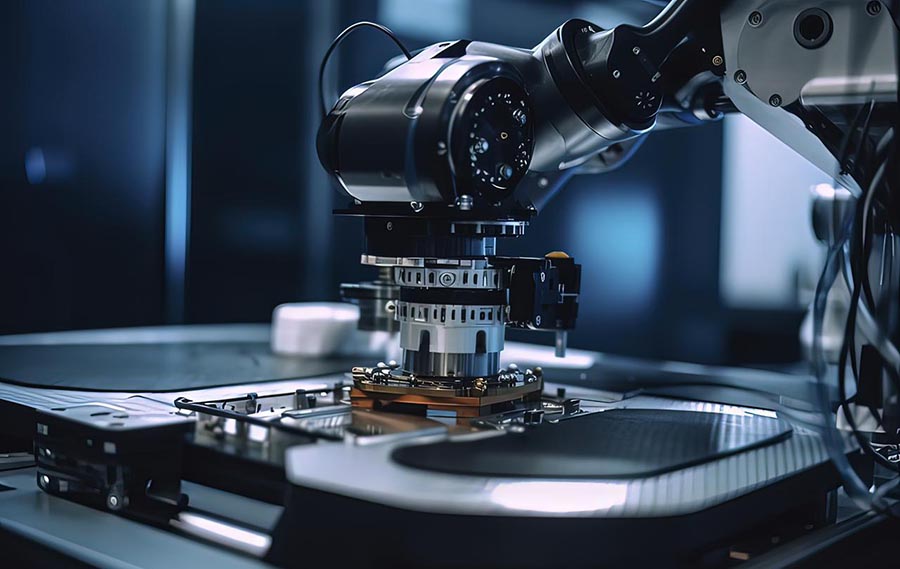

- Digital Collaboration:Deep integration of MES and ERP further enhances Turnkey’s transparency and response speed, allowing low-volume projects to enjoy high-volume-level management efficiency.

6、Conclusion: Match the Model to Project Traits, Avoid a “One-Size-Fits-All” Approach

Turnkey and Consignment each have pros and cons. There is no absolute best, only what best matches the project’s traits and stage. For low to mid-volume projects, if the goals are rapid time-to-market, reduced management burden, and unified quality/compliance, Turnkey is often the more robust choice. If a mature supply chain already exists and cost control is extremely sensitive, Consignment is viable, but requires accepting more coordination and quality risk.

About Tortai Technologies Co., Ltd.

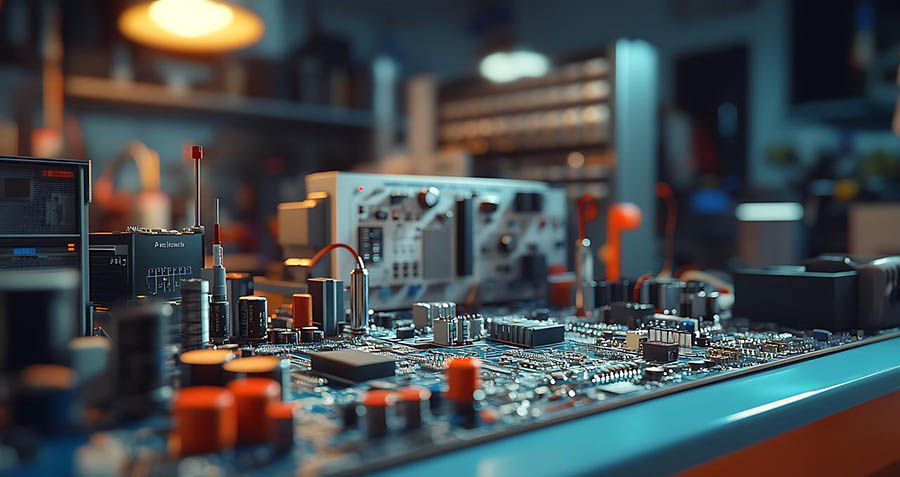

Tortai Technologies provides flexible dual-mode services (Turnkey & Consignment) in PCBA/OEM/ODM/EMS and can smoothly transition between modes based on project needs. We operate a 4000m² modern workshop with 4 fully automated high-speed SMT lines, 2 DIP lines, and ICT/FCT test lines. Certified to ISO9001:2015, ISO13485, and IATF16949, we execute to IPC-A-610J CLASS III standards and are equipped with an MES traceability system. This ensures that for both Turnkey and Consignment projects, we achieve the optimal balance of quality, delivery, and cost for low to mid-volume production.