Within the PCBA (Printed Circuit Board Assembly) manufacturing process, functional testing serves as a critical step in ensuring product performance and reliability. However, we frequently receive feedback from clients highlighting challenges encountered during functional verification after circuit board soldering and assembly. This can lead to product delivery delays or potential quality risks. TORTAI Electronics consistently prioritises addressing our clients’ pain points and is committed to delivering comprehensive solutions. To better address this challenge, we recently engaged in in-depth discussions with SPEA, a global leader in Automatic Test Equipment (ATE) manufacturing, gaining detailed insights into their advanced solutions.

Functional Testing Challenges and TORTAI’s Commitment

As electronic products grow increasingly complex, PCBA functional testing becomes more intricate. Traditional testing methods may encounter:

1、Insufficient test coverage: Difficulty comprehensively covering all functional points, leaving potential defects undetected.

2、Inefficient testing: Manual testing is time-consuming and labour-intensive, impacting production throughput.

3、Difficult fault diagnosis: Challenges in rapidly pinpointing fault causes prolong repair cycles.

4、High testing costs: Significant investment in specialised test fixtures and manpower.

TORTAI recognises that reliable functional testing is the cornerstone of delivering high-quality PCBA products. We not only provide professional PCBA manufacturing services but are also committed to alleviating our clients’ concerns regarding testing and validation. We continuously invest in R&D and explore cutting-edge technologies to ensure every PCBA unit meets the highest standards upon leaving our factory.

Discovering SPEA: Exploring Efficient, Precise Testing Solutions

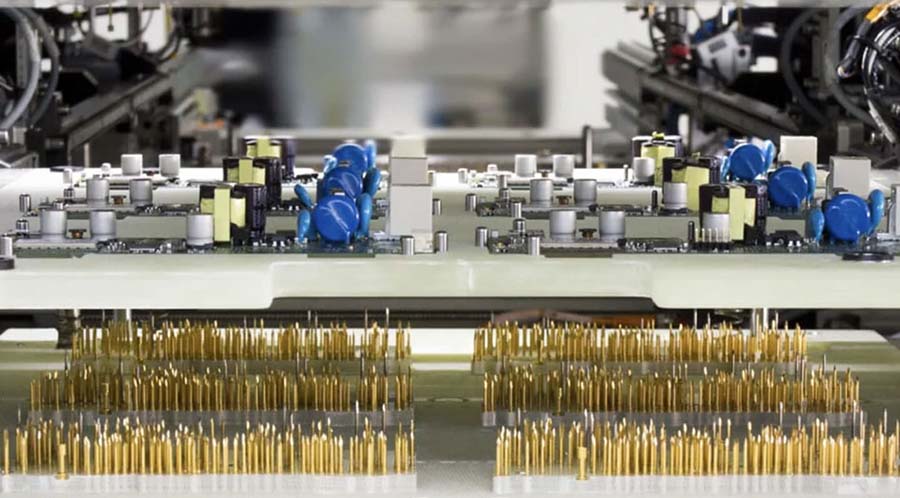

As a leader in the ATE industry, SPEA’s testing equipment is renowned for its ‘high precision, high efficiency, and high coverage,’ particularly excelling in PCBA ICT (In-Circuit Testing) and functional testing. We recently engaged in detailed discussions with SPEA, gaining comprehensive insights into the advantages of their testing equipment across the following areas, and are currently evaluating the potential for future implementation:

1、High Test Coverage: SPEA’s testing platforms deliver comprehensive coverage, encompassing open/short circuit detection, component parameter verification, and functional simulation, ensuring every aspect of the PCBA undergoes thorough validation.

2、Test Automation and Efficiency Enhancement: Highly automated testing processes significantly reduce test duration and boost production efficiency, meeting the rapid delivery demands of small-to-medium batches with diverse product varieties.

3、Precise Fault Diagnosis: Advanced diagnostic tools rapidly pinpoint fault locations on PCBA, substantially shortening repair and rework times while lowering production costs.

4、Flexible Testing Solutions: SPEA’s modular design and programmability enable its equipment to adapt flexibly to diverse PCBA testing requirements across varying types and complexities, delivering bespoke testing solutions for clients.

Gaining in-depth understanding of SPEA’s advanced testing technology represents a crucial step for TORTAI Electronics in continuously enhancing our testing capabilities and safeguarding client product quality. We remain focused on cutting-edge testing technologies and equipment within the industry, actively evaluating their integration into our production and quality control systems.

Beyond the sophistication of testing equipment, we prioritise deep collaboration with our clients. From engaging at the DFM (Design for Manufacturability) stage to provide testability design recommendations, through rigorous quality control during production, to comprehensive pre-shipment testing and traceability, we deliver a one-stop PCBA/EMS solution. This ensures every step of your project—from design to mass production—is efficient and reliable.

TORTAI Electronics is committed to becoming your most trusted PCBA/EMS partner. We understand that only by continuously enhancing our comprehensive capabilities in manufacturing and testing can we genuinely assist clients in overcoming production challenges, jointly achieving product excellence and market success.

Should you encounter challenges in PCBA functional testing or seek a high-quality, highly reliable PCBA/EMS partner, please do not hesitate to contact us. Let us join forces to safeguard your product quality and accelerate your market success!