In modern electronic product development, complex circuit design is the core of realising high-performance and high-reliability products. However, how to ensure that the design can be efficiently transformed into high-quality products, which puts strict requirements on the technical strength of PCBA factories. In this paper, we will show how PCB assembly can support the realisation of complex circuit design through specific successful cases, and provide professional reference for customers.

1、The project background: customer needs and challenges

1.1 Highly complex circuit design

An intelligent equipment company developed a high-end industrial control product that required a circuit board that supported multi-functional integration and high-speed signal processing. The design includes multi-layer PCB wiring, micro-pitch component soldering, and high-frequency signal interference control, placing extremely high demands on the production process of the PCBA factory.

1.2 Short-term mass production

The customer not only needs to ensure the functional realisation of the design, but also requires the completion of small batch trial production and validation in a short period of time, and plans for rapid mass production based on market feedback. This poses a challenge to the flexibility and responsiveness of PCBA factories.

2、PCBA factory solutions

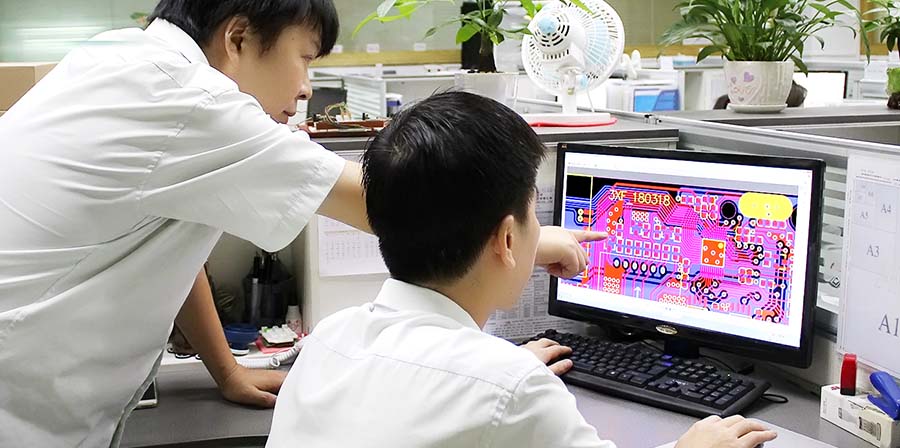

2.1 Professional technical team support

Factory in the project start-up phase and the customer to carry out in-depth communication, through the participation of the technical team to help customers optimise the circuit board design, to solve potential problems that may affect manufacturability. This includes optimising component layout, reducing wiring cross-interference and so on.

2.2 Advanced Production Equipment Guarantee

For multi-layer PCB and micro-pitch component soldering, the factory uses high-precision placement equipment and lead-free soldering process to ensure the precision and reliability of component soldering. In addition, by introducing 3D SPI (Solder Paste Inspection) and AOI 3D (Automated Optical Inspection 3D), the factory realises full-process quality monitoring during the production process.

2.3 Customised Process Flow

The factory has specially tailored impedance control schemes and signal integrity testing processes according to the high-frequency signal characteristics of the customer’s products. These targeted process adjustments ensure the high performance output of the product while minimising signal interference problems.

3、Project Achievement: Efficient Delivery from Trial Production to Mass Production

3.1 Successful pilot production verification

In just three weeks, the factory completed the production and testing of the first batch of 50 prototypes, and passed the customer’s strict verification. All key parameters meet the design requirements, laying a solid foundation for subsequent mass production.

3.2 Cost optimisation during mass production

During the mass production stage, the factory further optimised the cost through large-scale production. Specific measures include optimising the supply chain to reduce the purchase price of components and streamlining some of the non-critical testing processes, thus helping the customer to significantly reduce the cost of a single board.

3.3 The basis for long-term co-operation

As a result of the outstanding performance in the project, the customer listed the PCBA factory as its long-term partner. In the subsequent development of a number of complex products, the two sides continue to maintain efficient cooperation, further consolidating the customer’s trust in the factory’s technical capabilities.

4、Technical highlights in successful cases

4.1 Integrated design and manufacturing services

By deeply participating in the customer’s circuit design optimisation, the factory not only improves the manufacturing efficiency, but also effectively reduces the risk of trial production failure.

4.2 Full-flow Quality Control Guarantee

From solder paste testing to final product testing, the factory adopts advanced testing methods at every step to ensure a high yield rate.

4.3 Continuous optimisation and customer feedback

The factory not only pays attention to the efficiency improvement in the production process, but also takes the initiative to collect the feedback from customers in the actual application to continuously optimise the product performance and production process.

Conclusion

Through this successful case, PCB assembly shows the important role in the realisation of complex circuit design. From design optimisation to production landing, to cost control and quality assurance, the technical capabilities of the PCBA factory provides customers with solid support. For enterprises, choosing a PCBA factory with rich experience and advanced technology is undoubtedly an important guarantee for product success.