The PCBA coating thickness standard requires that the normal thickness of the coating of most circuit board products is 25 to 127 microns, and some products may have lower coating thickness.

The following is the method of measuring the coating thickness of PCBA three-resistant paint using a tool:

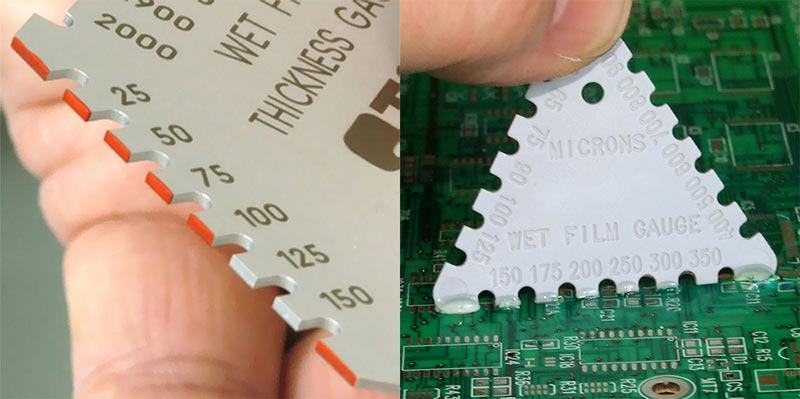

1.Wet film thickness meter: The wet film thickness meter is a special instrument that can directly measure the thickness of the wet film coated on the circuit board. There is usually a series of grooves on the instrument, each with a known calibration length. A wet film thickness meter is placed on the wet film, the depth of the groove is measured, and then this measurement is multiplied by the solid percentage of the coating to calculate an approximate dry coating thickness.

2.Micrometer: A micrometer can be used to measure thickness at multiple locations on the board before and after coating. Measure the thickness of the cured coating and subtract the thickness without coating, then divide by 2 to get the coating thickness on one side of the board. The standard deviation of the measured value can also be calculated to determine the uniformity of the coating. Micrometer measurements are best done using a harder coating that will not deform under pressure.

3.Ultrasonic thickness gauge: Ultrasonic thickness gauge is a tool that uses ultrasonic technology to measure the thickness of the coating. It has many advantages over eddy current probes because it does not require a metal back. Ultrasonic thickness gauges determine the thickness of the coating by measuring the amount of time it takes for sound to travel from the transducer, through the coating, and then reflect back off the PCB surface. This method is relatively safe and will not cause damage to the PCB.