With the electrochemical energy storage in the power system continues to promote the application, there is a container type mobile energy storage system is entering people’s vision, the difference between the traditional energy storage power station needs to build a special plant, the construction cycle is long and fixed can not be moved, the mobile energy storage system can be factory production, with a strong adaptability to the environment, easy to install, high scalability features, at present, more and more mobile energy storage trekking and being transported to all parts of the motherland.

Containerised mobile energy storage system generally consists of energy storage battery system, monitoring system, battery management unit, special fire protection system, special air-conditioning, energy storage converter and isolation transformer, and finally integrated in a 40-foot container. The layout effect of a single box is shown below:

Internal structure of mobile energy storage system

The battery system is mainly composed of series-parallel connection of battery cells: firstly, a dozen groups of battery cells are connected in series-parallel to form a battery box, then the battery box is connected in series to form a battery pack series and raise the system voltage, and finally, the battery pack series are connected in parallel to raise the system capacity, and are integrated and mounted in the battery cabinet.

The monitoring system mainly implements the functions of external communication, network data monitoring and data acquisition, analysis and processing to ensure accurate data monitoring, high accuracy of voltage and current sampling, data synchronisation rate and fast execution of remote control commands; the battery management unit has a high-precision single-unit voltage detection and current detection to ensure the voltage balance of the battery cell module and avoid the generation of circulating currents between the battery modules, which affects the system operation efficiency.

The container is also equipped with special fire-fighting and air-conditioning systems to ensure the safety of the system, in which the fire-fighting system senses the fire alarm through smoke sensors, temperature sensors, humidity sensors, emergency lights and other safety equipment, and automatically extinguishes the fire; special air-conditioning system according to the external ambient temperature, the air-conditioning system through the thermal management strategy control of cooling and heating, to ensure that the temperature inside the container is in the right zone, to extend the service life of the battery.

The energy storage converter is an energy conversion unit that converts the DC power of the battery into three-phase AC power, and it can be operated in both grid-connected and off-grid modes. In grid-connected mode, the converter interacts with the grid in accordance with the power command issued by the upper level dispatch; in off-grid mode, the converter can provide voltage and frequency support for the plant loads and provide black start power for some renewable energy sources. The outlet of the storage converter is connected to an isolation transformer, which completely insulates the primary side from the secondary side of the electrics and ensures the maximum safety of the container system.

At present, mobile energy storage system with its more prominent flexibility and convenience has been widely used in power system transmission and distribution and other fields. Compared with the traditional fixed energy storage power station, the modular design of the container energy storage system adopts the international standardised container size, which allows ocean and road transport, and can be lifted and loaded by overhead cranes, which is highly movable and not subject to geographical constraints. In addition, the container energy storage system can be factory-produced and directly assembled and commissioned in the workshop, which greatly saves the construction and operation and maintenance costs of the project and achieves accident isolation.

This kind of compact structure, engineering construction cycle is short, can quickly respond to customer demand for mobile energy storage system has become the future mainstream of electrochemical energy storage grouping method hope. And in the future, with the continuous breakthrough of the battery body technology, the energy density of the mobile energy storage system will also be further improved, the cost is also greatly reduced, the future is expected to become an important carrier to promote the revolution of energy production and consumption, and is a very promising technology and industry in the energy Internet.

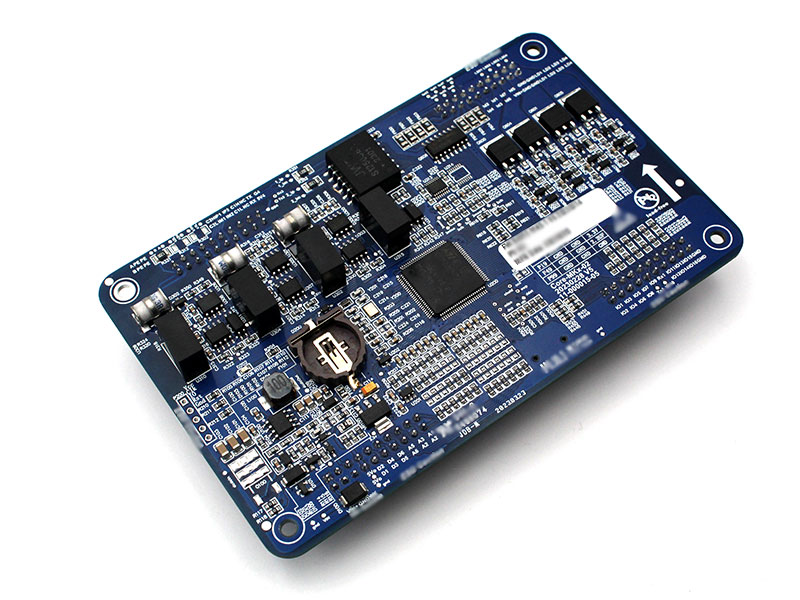

After PCBA is assembled, a series of tests are required to ensure the performance and reliability of the product. The tests include:

Welding quality test: testing the welding quality of the welding point, including welding strength, welding temperature, etc.

Electrical performance test: test the electrical performance of PCBA, including input and output voltage, current, power, waveform, etc.

Reliability test: test the reliability of PCBA under different environmental conditions, including temperature, humidity, vibration, etc.

Function Test: Test whether the function of PCBA meets the design requirements, including the test of communication, control, data processing and other functions.

Energy storage system is a kind of equipment that stores electrical energy and releases it when needed, featuring high efficiency, high reliability, long life, high safety and environmental protection.