What is component cold soldering? Why does component cold soldering occur? What should be done about component cold soldering?

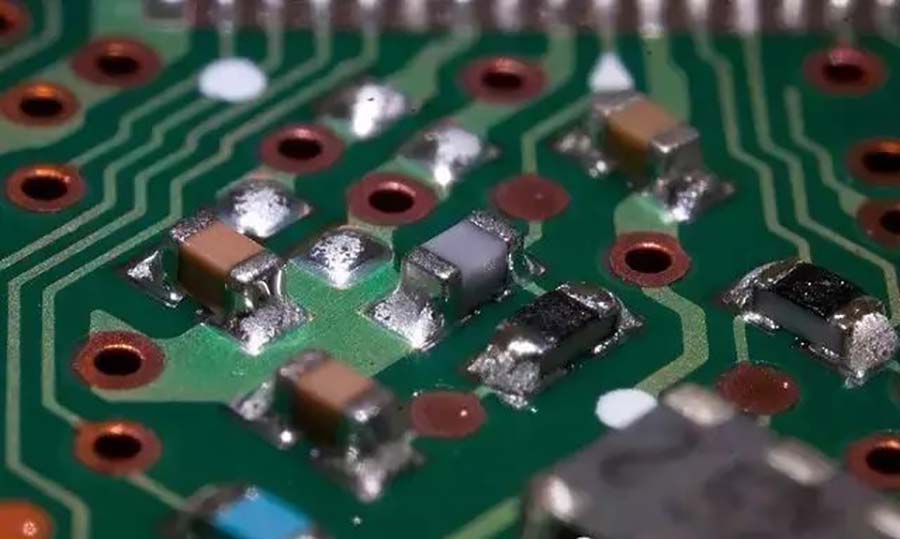

On the production line of a factory, there is a specific model of circuit board that needs to be assembled. This circuit board has multiple surface-mounted components, such as chips, capacitors, and resistors. During a batch production run, the issue of component cold soldering arose. After analysis, the following situations were found to potentially cause component cold soldering. Let’s take a look together.

What is component solder joint failure?

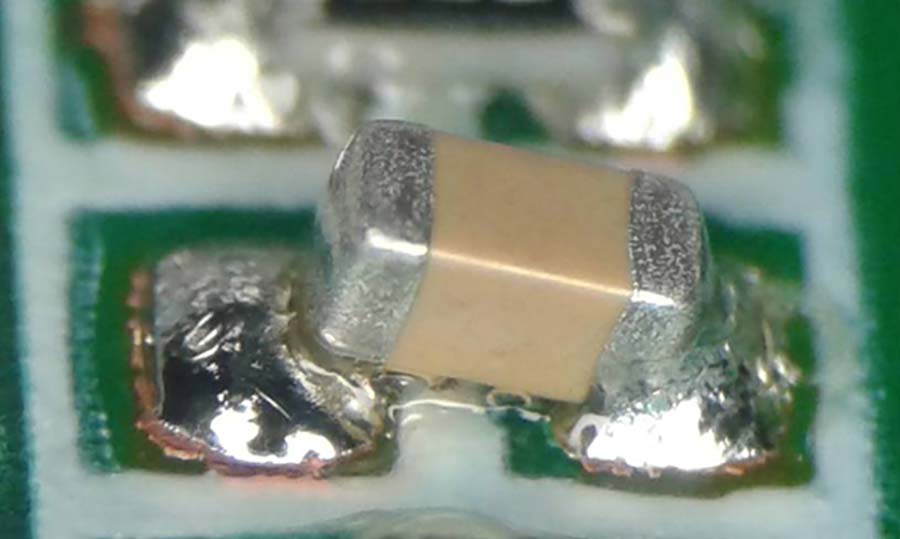

Component solder joint failure refers to the phenomenon where, during the soldering process, the connection between the solder joint and the component or circuit board becomes unstable or unreliable due to various reasons. Solder joint failure may lead to circuit malfunctions, signal transmission issues, and unreliable device performance. Component solder joint failure may have the following impacts:

1、Unreliable electrical connections: Solder joint failure can cause unstable connections between the solder joint and the component or circuit board. This may result in poor current transmission, causing circuit failures or performance degradation. Unreliable electrical connections may also lead to unstable signal transmission, affecting the normal operation of the device.

2、Resistance changes: Poor connections caused by solder joint defects may result in changes in resistance values. Resistors in circuits are selected according to design requirements, and solder joint defects may cause resistance values to exceed the design range, thereby affecting circuit power consumption and performance.

3、Temperature issues: Cold soldering may cause poor contact between solder joints and components or circuit boards, leading to localised current overload or current imbalance. This can cause localised temperature increases, potentially triggering overheating issues that damage components and circuit boards.

4、Reliability issues: Cold soldering may cause connections between components and circuit boards to become unstable. Under prolonged use or high-load conditions, these unstable connections may loosen or disconnect, leading to reduced device reliability.

Causes of component solder joint defects

The following are some factors that may cause component solder joint defects:

1、Humidity and environmental conditions: Humidity and environmental conditions in the soldering environment significantly impact soldering quality. Excessive humidity may cause oxidation or corrosion in the soldering area, affecting soldering quality. Additionally, changes in environmental temperature and humidity may also have a negative impact on soldering quality.

2、Design issues: The design and layout of solder joints may also influence solder joint defects. If the soldering points are too small, too densely packed, or too close to other components, this may result in poor soldering and solder joint defects.

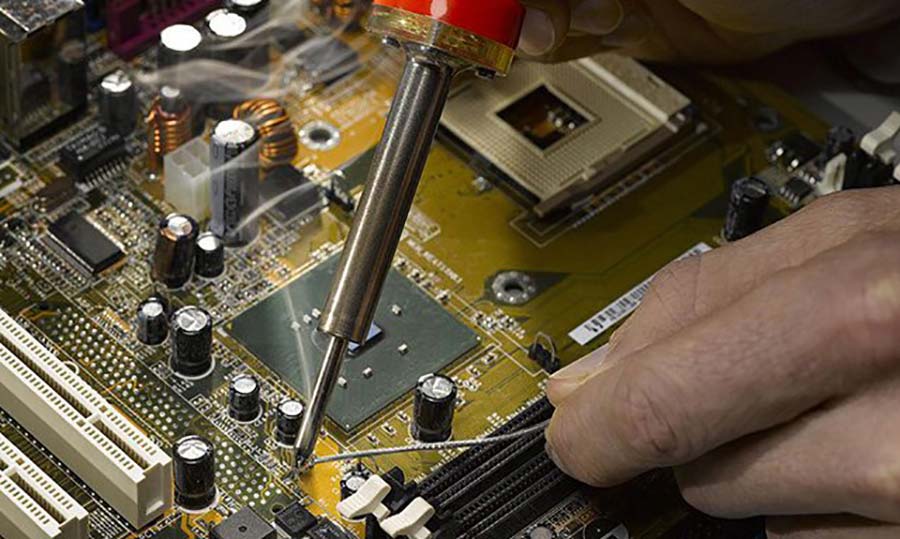

3、Inappropriate soldering techniques: Different types of components require appropriate soldering techniques. For example, surface-mount components require soldering using a hot air oven or reflow soldering technology, while through-hole components may require manual soldering. Using inappropriate soldering techniques may result in poor soldering and solder joint defects.

Solutions

Measures to control solder joint defects:

1、Ensure a suitable soldering environment: Solder joint defects are often related to the soldering environment. Ensure that the temperature in the soldering area is appropriate and that there is no excessive humidity or dryness. Use appropriate soldering tools and equipment, and ensure that the soldering area is clean.

2、Inspect the quality of components and solder joints: After soldering is complete, carefully inspect the quality of components and solder joints. Ensure that the solder joints have the correct shape and no obvious defects or cracks. Use a magnifying glass or microscope for inspection and test the solder joints to ensure they are securely connected.

3、Use appropriate soldering materials: Selecting the right soldering materials is also key to resolving cold soldering issues. Use high-quality solder wire and flux to ensure the stability and reliability of the soldered connections. Additionally, ensure that the soldering materials are compatible with the components and circuit board materials.

4、Training and technical support: Providing training and technical support on soldering techniques is crucial for electronic device manufacturing and maintenance personnel. Through training, they can learn proper soldering techniques and operating methods, as well as how to identify and resolve solder joint defects.

5、Select appropriate soldering techniques: Different components and circuit boards require different soldering techniques. For example, for surface-mount components, using a hot air oven or reflow soldering technique can provide more reliable solder connections. For through-hole components, manual soldering may be more suitable. Selecting the appropriate soldering technique can reduce the risk of cold solder joints.

6、Quality Control and Inspection: Implementing effective quality control and inspection measures during the manufacturing process can reduce the occurrence of cold solder joints. Using automated equipment for soldering and inspection can improve the accuracy and consistency of soldering and detect potential cold solder joint issues early on.