In the electronics manufacturing industry, subtle oversights in conformal coating processes can lead to critical product failures. A recent incident during the coating of a new medical product sample, where incorrect coverage caused functional failure, has prompted the following insights.

In 2023, a medical device manufacturer suffered total failure of new samples during testing, resulting in direct financial losses exceeding one million CNY. The root cause was neither a design defect nor component quality issues, but rather coating voids formed during the conformal coating process. These voids created localized humid environments, accelerating electrochemical corrosion on the circuit board. This case reveals a critical fact: the quality control of the conformal coating process directly determines the reliability and service life of electronic products.

As electronic products evolve towards higher density and multi-functionality, conformal coating has transitioned from a simple “protective layer” to a key process influencing product performance. This article provides an in-depth analysis of typical cases of functional failure caused by conformal coating and offers practical mitigation strategies for electronics manufacturers.

1、Typical Case Analysis of Conformal Coating Failures

Case 1: Electrochemical Corrosion Caused by Coating Voids

In a medical device sample, large voids in the conformal coating left component pins partially exposed. Under the influence of electric fields, these areas experienced electrochemical corrosion, where the metal pin surfaces corroded into small holes, ultimately leading to pin breakage and module detachment.

Failure Mechanism Analysis:

- Coating voids create localized humid environments, accelerating corrosion reactions.

- Corrosion rates multiply in areas with concentrated electric fields, such as pins.

- Instead of providing protection, the coating, due to its voids, created a more severe localized environment.

This type of failure typically accelerates in hot and humid environments, remains hidden initially, and is difficult to detect in early stages, but can lead to complete equipment malfunction over time.

Case 2: Stress Failure Caused by Material Incompatibility

A maritime electronic equipment module used LY12 (2A12) material and was coated with conformal coating. After 240 hours of military standard damp heat testing, a “white powder” phenomenon appeared (mistaken for mold), which was actually a corrosion failure due to material incompatibility.

Root Causes:

- Improper selection of aluminum alloy material; LF series anti-rust aluminum alloy or LD31 (6063) should have been used instead.

- Hard aluminum materials exhibit poor corrosion resistance in damp heat environments.

- Insufficient compatibility between the conformal coating and the base material accelerated the corrosion process.

Such issues are particularly prominent in coastal areas, where salt spray environments significantly accelerate the corrosion process, leading to premature equipment failure.

Case 3: Coating Defects Caused by Improper Process Parameters

An industrial control device experienced internal stress due to excessively thick conformal coating (exceeding 500μm). This stress acted upon component pins, ultimately causing them to break under thermal expansion and contraction.

Process Errors:

- Coating thickness was controlled based on feel, without using a thickness gauge for monitoring.

- Curing conditions were not met, with only surface drying achieved before proceeding to the next step.

- The impact of coating thickness on heat dissipation performance was overlooked.

Table: Conformal Coating Thickness Requirements and Common Issues

| Coating Type | Recommended Thickness Range | Risks of Too Thin (< Lower Limit) | Risks of Too Thick (> Upper Limit) |

|---|---|---|---|

| Acrylic Resin (AR) | 0.03mm ~ 0.13mm | Discontinuous protection, vulnerabilities | High internal stress, affects heat dissipation |

| Epoxy Resin (ER) | 0.03mm ~ 0.13mm | Prone to pinholes, poor protection | Brittle, easy to crack |

| Polyurethane (UR) | 0.03mm ~ 0.13mm | Insufficient wear resistance | Difficult to cure, solvent entrapment |

| Silicone Resin (SR) | 0.05mm ~ 0.21mm | Poor protection effect | Excessive flexibility, weak mechanical protection |

2、Investigation of Root Causes for Conformal Coating Failures

2.1 Improper Material Selection

The selection of conformal coating materials requires comprehensive consideration of the application environment, substrate characteristics, and process requirements. Common mistakes include:

- Ignoring Environmental Suitability: Failure to use silicone-based conformal coating with good high-temperature resistance in high-temperature environments (e.g., engine compartments), or failure to choose acrylic conformal coating with excellent moisture resistance in high-humidity environments (e.g., seaside).

- Lack of Compatibility Testing: Not testing the compatibility between the conformal coating and components on the PCB (such as soft plastics, enameled wires) may lead to material dissolution or cracking. For example, in one case, silver-plated components in contact with an aluminum alloy caused galvanic corrosion, which was resolved only after changing the housing plating to nickel.

2.2 Inadequate Pre-treatment

Contaminant residues are a leading cause of conformal coating failure. Post-soldering PCB surfaces may retain ionic contaminants such as flux residues, hand sweat, and dust. If not thoroughly removed, these can accelerate circuit corrosion under humid conditions when encapsulated by the conformal coating.

Solutions include using appropriate cleaning agents (e.g., hydrocarbons, alcohols) with ultrasonic or spray equipment for cleaning, followed by sufficient drying at temperatures of 80-100°C. Research indicates that failures due to inadequate pre-treatment account for over 40% of conformal coating problems.

2.3 Imprecise Control of Process Parameters

The conformal coating process involves multiple parameters where slight deviations can lead to serious consequences:

- Coating Thickness Control: The IPC standard allows for a dry film thickness between 30-130 microns. Too thin a coating cannot form a continuous protective film, while too thick a coating may lead to solvent entrapment, coating cracking, or excessive internal stress during temperature changes.

- Failure to Meet Curing Conditions: Proceeding to the next step after only surface drying is a common error. When the conformal coating is not fully cross-linked and cured internally, its electrical, mechanical, and protective properties do not reach optimal states. For instance, UV conformal coating requires complete curing to achieve the expected hardness (typically 2H-4H pencil hardness) and protective effect.

3、Detection and Diagnostic Methods for Conformal Coating Failures

3.1 Visual Inspection and Microscopic Analysis

Macroscopic inspection can reveal obvious defects like uneven coating, bubbles, and sagging. However, for micron-level defects, microscopy is necessary, especially for observing key areas such as around pins and beneath fine-pitch components.

Bubble analysis needs to distinguish between vacuum bubbles and solvent bubbles. The former are often due to improper coating processes, while the latter are related to the curing process. Large bubbles (diameter >0.5mm) are usually visible to the naked eye, whereas micro-bubbles require magnification tools.

3.2 Performance Testing and Reliability Validation

- Electrical Performance Testing: Includes tests like insulation resistance and dielectric strength to evaluate the impact of the conformal coating on circuit performance. Particularly for high-frequency circuits, changes in the dielectric constant of the coating can affect signal transmission.

- Environmental Adaptability Testing: Validates the performance of the conformal coating under extreme conditions through tests such as thermal shock, high temperature/high humidity, water resistance, and salt spray resistance. For example, automotive electronics require validation of reliability under temperature cycling from -40°C to 125°C.

- Adhesion Test: Uses the GB/T 9286-1998 standard cross-cut test method (checkerboard test) to assess the bonding strength between the coating and the substrate. A high-quality conformal coating should achieve a grade of 0 (completely smooth cut edges) or 1 (no more than 5% damage).

4、Mitigation Strategies and Solutions for Conformal Coating Failures

4.1 Material Selection Optimization Strategy

Selection Based on Application Environment:

-

- High-temperature environments (e.g., engine bays): Choose silicone conformal coating, which has a wide temperature range (up to 200°C).

- High-humidity environments (e.g., coastal equipment): Choose acrylic conformal coating, which has good moisture resistance.

- Equipment requiring frequent repair: Choose repairable conformal coatings (e.g., silicone, some polyurethanes).

- Compatibility Testing: Before full-scale use, always perform compatibility tests by applying the coating to sensitive materials and observing any changes. Also consider the interaction between the conformal coating and solder flux residues to avoid inhibition of curing or deterioration of insulation performance.

4.2 Process Control Refinement

- Pre-treatment Standardization: Establish strict cleaning and drying procedures to ensure the board surface is clean and dry. Use specialized cleaning agents for different contaminants (e.g., flux, grease, fingerprints).

- Coating Thickness Control: Use a thickness gauge for real-time monitoring, keeping the dry film thickness within an appropriate range (typically 50-150μm). Avoid applying too thick a coat at once; instead, adopt a strategy of multiple thin layers, aiming for an even thickness of 30-50 microns per layer.

- Curing Process Optimization: Strictly follow the curing conditions (temperature, humidity, time) specified in the product technical data sheet. For UV conformal coatings, ensure precise control of UV intensity, exposure time, and distance parameters.

4.3 Design for Conformal Coating

- DFM (Design for Manufacturability) Principles: Consider conformal coating requirements during the PCB layout stage, such as concentrating connectors or other non-coated areas on the same side to improve coating efficiency and quality.

- Masking Strategy: Use specialized pressure-sensitive tapes or liquid maskants for precise protection of non-coating areas. For high-volume production, creating high-precision laser fixtures is an efficient and reliable choice.

5、Advanced Conformal Coating Technologies and Future Trends

5.1 New Material Applications

- Environmentally Friendly Conformal Coatings: With increasingly stringent environmental regulations, solvent-free, low-VOC (Volatile Organic Compound) conformal coatings are becoming a trend. For example, water-based conformal coatings require VOC content below 50g/L to comply with EU environmental standards.

- Functional Conformal Coatings: Coatings with additional functions such as fire resistance, high temperature resistance, and anti-static properties are continuously emerging to meet the needs of special application scenarios. For instance, the aerospace industry requires conformal coatings that can withstand extreme temperatures and resist electrostatic interference.

5.2 Process Innovation and Intelligence

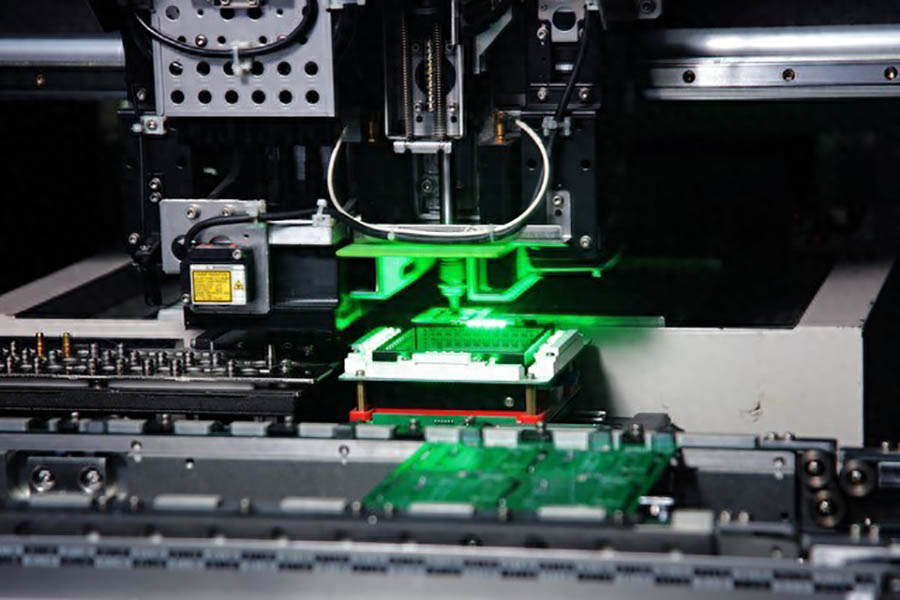

- Automated Coating Systems: The use of automated equipment like robotic spraying and selective coating improves coating consistency and efficiency. Statistics show that automated coating can reduce defect rates by over 60%.

- Real-time Monitoring Technology: Integrating systems like thickness sensors, humidity monitoring, and cure degree detection enables real-time feedback and adjustment of process parameters.

- 2K Two-Component Systems: New two-component conformal coating materials allow for thicker coating layers and perfect coverage, achieving a higher level of protection. These materials significantly improve coating consistency through precise control of mixing ratios and the curing process.

Conformal coating, as a key process in electronics manufacturing, directly impacts product reliability and lifespan. Through systematic material selection, strict process control, and comprehensive testing and validation, the risk of failure due to conformal coating can be significantly reduced.

As the application environments for electronic products become increasingly complex, conformal coating technology is developing towards environmental sustainability, functionality, and intelligence. Companies must establish a comprehensive conformal coating management system, implementing refined control from design, material selection, and processing to inspection, to remain competitive in the fierce market competition.

Tortai Technologies has been deeply involved in the electronics manufacturing industry for many years. We understand the critical impact of conformal coating on product reliability. Our technical team possesses extensive experience in conformal material selection and process optimization, enabling us to provide customers with full-process solutions from design and process control to failure analysis. In an era of increasing precision and reliability demands for electronic products, Tortai Technologies is committed to working with customers to overcome the technical challenges of conformal coating and ensure the long-term stable operation of electronic products.