In the medical electronics manufacturing sector, the selection of a test strategy has evolved from a purely technical consideration to a core decision impacting product quality. In 2025, a well-known patient monitor manufacturer faced a product recall due to batch-level inspection escapes. The root cause was neither a design flaw nor a process issue, but the incorrect application of a traditional bed-of-nails test on a high-density PCBA, which failed to detect soldering defects in fine-pitch BGA components. This case reveals a critical truth in medical electronics manufacturing: the appropriateness of the test strategy directly determines product reliability and safety.

As medical devices advance towards higher density and multi-functionality, PCBA testing has evolved from a single-method approach into a systems engineering task involving multiple synergistic technologies. Choosing the right test strategy is not only about cost efficiency but also directly affects patient safety and clinical outcomes. This article provides an in-depth analysis of the technical characteristics of ICT, Flying Probe, and Functional Testing, offering a scientific selection framework for medical electronics manufacturers.

1. Principles of the Three Major Test Technologies and Medical Industry Specificities

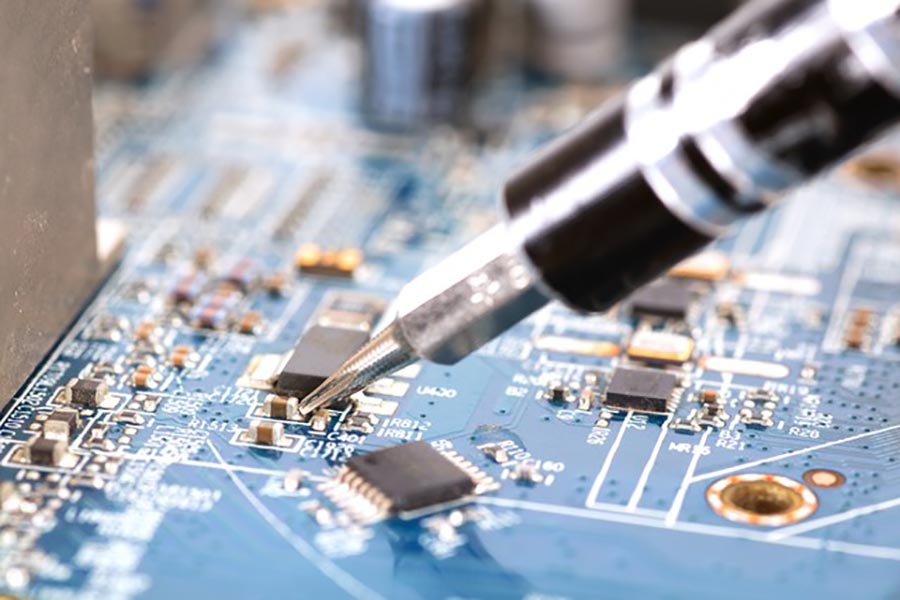

ICT Testing: The Quality Bulwark for Mass Production ICT (In-Circuit Test) is an automated electrical testing method for PCBAs using a bed-of-nails fixture. Its core principle involves accessing component pins or circuit nodes through pre-defined test points to statically verify the correctness and connectivity of individual components.

In the medical electronics field, ICT holds particular value. Medical devices often require 24/7 operation and may have service lives of 5-10 years, placing extremely high demands on the long-term stability of components and soldering reliability. ICT can perform precise value measurements on passive components like resistors, capacitors, and inductors, with error margins potentially controlled within ±1%, far exceeding the ±5% tolerance common in consumer electronics.

The high fault coverage of ICT (often above 90%) makes it the preferred test solution for high-risk medical devices like defibrillators and pacemakers. Using a fixture, ICT can test thousands of points simultaneously, with per-board test times ranging from a few seconds to tens of seconds, making it particularly suitable for high-volume production environments.

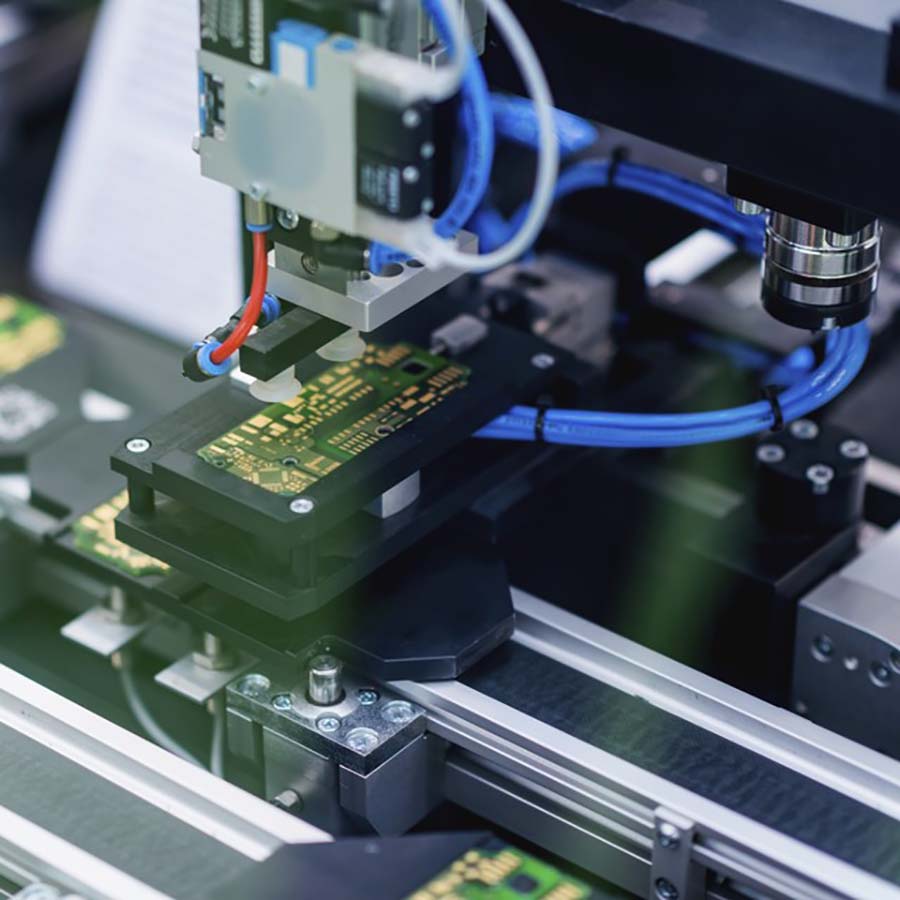

Flying Probe Testing: The Flexible Solution for High Density and Low Volume Flying Probe testing is a fixtureless test technology that uses 2 to 8 independently movable probes to make direct contact with PCBA test points for measurement. Its greatest feature is the elimination of dedicated fixtures, using software to control the probe path for flexible access to test points.

For the growing trend towards high-density interconnects and miniaturization in medical electronics, Flying Probe testing shows unique advantages. Its test pitch can reach 0.2mm, with probe positioning accuracy of 5-15 microns, enabling effective testing of miniature components like 01005 chips and 0.3mm pitch BGAs. This precision is crucial for the intricate PCBAs found in implantable medical devices and portable diagnostic equipment.

The rapid changeover capability of Flying Probe testing is especially suited for the low-volume, high-mix production models common in medical device manufacturing. While traditional ICT fixture development can take up to 160 hours, Flying Probe test program development may require only 4-6 hours, significantly shortening time-to-market.

Functional Testing: The Final Defense in System-Level Validation Functional Test (FCT) is a method to verify from a system level whether a PCBA operates as designed. It simulates real-world operating conditions, applying input signals and detecting output responses to ensure the entire system—not just individual components—meets specifications.

In medical devices, Functional Testing holds irreplaceable value. The safety of life-support equipment like ventilators and infusion pumps depends not only on component functionality but on the reliable of the entire system. FCT can validate the integration of software and hardware, which ICT and Flying Probe tests cannot achieve.

Functional testing for medical devices typically includes special requirements such as safety performance tests (e.g., leakage current, insulation resistance), EMC/EMI tests, and environmental adaptability tests, ensuring device reliability in clinical settings.

Table: Comparison of Three Major Test Technologies

| Characteristic | ICT Test | Flying Probe Test | Functional Test |

| Test Focus | Component Level | Nets & Components | System Level |

| Fault Coverage | High (>90%) | Medium-High (70-85%) | System-Function Oriented |

| Initial Setup Time | Long (1-4 weeks) | Short (1-2 days) | Medium (1-2 weeks) |

| Per-Board Test Time | Short (Seconds) | Long (Minutes) | Medium (Minutes) |

| Suitable Volume | High Volume | Low Volume / Prototype | All Volumes |

| Initial Investment | High (Fixture Cost) | Medium (Equipment Cost) | Medium-High (System Cost) |

2. Selection Strategy: A Multi-Dimensional Consideration Based on Product Characteristics and Production Scale

Correlation Between Medical Device Risk Class and Test Strategy The risk classification of a medical device directly dictates the rigor of the test strategy. According to standards like IEC 60601-1, devices are classified as Type B (body surface), Type BF (body cavity), and Type CF (cardiac contact), with CF having the strictest requirements.

For CF-type devices, a triple-test assurance is recommended: Flying Probe for prototype verification, ICT for in-process component-level control, and Functional Test as the final release criterion. This layered strategy ensures comprehensive quality control from components to system.

BF-type devices may employ an ICT + Functional Test combination, while B-type devices can select Flying Probe or ICT as the primary method based on complexity. Research indicates that companies employing differentiated test strategies can reduce quality costs by up to 25% while maintaining high reliability.

Production Scale and Economic Analysis Production volume is a core factor in test strategy selection. Cost-benefit analysis shows optimal choices differ significantly by scale:

- Prototype Stage (<50 boards):Flying Probe is optimal, requiring no fixture investment and allowing rapid response to design changes.

- Low-Volume Production (50-1,000 boards):Flying Probe or simplified ICT, decided based on product complexity.

- Medium/High-Volume Production (>1,000 boards):ICT demonstrates clear economic advantage as fixture costs are amortized.

For medical devices with long lifecycles (e.g., large imaging equipment), investing in ICT is worthwhile even with moderate annual production, as its high fault coverage reduces field failure risk and recall costs.

PCBA Complexity and Technical Match Component density and packaging types directly influence test method selection. For High-Density Interconnect (HDI) boards (line width/space ≤ 3 mil), fine-pitch BGAs (pitch <0.5mm), and components smaller than 01005, Flying Probe holds a distinct advantage, as its fine probes can access areas unreachable by traditional beds-of-nails.

Conversely, for PCBAs dominated by through-hole components with ample test points, ICT is more cost-effective. When a PCBA contains numerous analog and passive components, ICT’s parametric measurement capability provides more comprehensive quality assurance.

The Critical Role of Design for Test (DFT) Design for Testability is foundational for successful test strategy implementation. Proper DFT significantly improves test coverage and efficiency:

- Test Point Layout:ICT requires test points on a 2.54mm grid, while Flying Probe supports irregular layouts but requires probe accessibility.

- Boundary Scan:For high-density BGAs and nodes with limited access, Boundary Scan (IEEE 1149.1) can complement physical testing.

- Virtual Test Points:Access internal nodes via functional test interfaces to extend coverage.

Medical device PCBAs should prioritize test accessibility, ensuring critical signals and power nets are probe-able, forming the basis for high-quality testing.

3. Hybrid Strategy: Best Practices for Optimizing Test Efficiency and Coverage

Series Test Flow Design Advanced medical electronics manufacturers commonly adopt hybrid test strategies, combining the strengths of each technology for optimal results. A typical serialized flow includes:

- Prototype Stage → Flying Probe Test(for rapid feedback on design defects).

- Low-Volume Pilot Run → Flying Probe + Basic Functional Test(to validate process stability).

- Volume Production → ICT Test + Comprehensive Functional Test(to ensure consistency and reliability).

This strategy identifies different issues at different stages: Flying Probe catches design and process flaws, ICT detects manufacturing variations, and Functional Test verifies system performance. Practice proves hybrid strategies can reduce defect escape rates below 50 ppm.

Data Integration and Comprehensive Analysis The core value of a hybrid strategy lies in the integrated analysis of test data. Correlating parametric measurement data from ICT, network connectivity data from Flying Probe, and system performance data from FCT builds a complete quality profile.

For example, if a Functional Test detects signal distortion, one can trace it back to the offset voltage measurement of a related op-amp from ICT and the connectivity data of feedback network resistors from Flying Probe, enabling efficient root cause analysis.

The Art of Balancing Cost and Benefit A hybrid strategy requires finding equilibrium between test cost and quality benefit. Key balance points include:

- Number of Test Points:Increasing points improves coverage but adds cost; critical points must be determined via risk analysis.

- Test Frequency:Critical medical PCBAs may require 100% testing, while non-critical sub-assemblies may use sampling.

- Test Depth:Balancing the ratio of parametric testing (ICT) to functional verification (FCT), decided based on device criticality.

A well-designed hybrid strategy achieves the optimal balance between quality and cost, minimizing the total cost of quality.

4. Special Considerations and Implementation Challenges for Medical Electronics Testing

Regulatory Compliance Requirements Medical device test strategies must meet stringent regulatory requirements, including ISO 13485 QMS, IEC 60601-1 safety standards, and FDA 21 CFR Part 820. These regulations impose special demands on test traceability and documentation.

Test systems must provide complete audit trails, recording test results, conditions, and equipment calibration status for each PCBA. For implantable devices, test data retention must exceed the device’s expected life by at least two years, ensuring full traceability.

Adaptation to Clean and Sterile Environments Medical PCBA testing environments may have special requirements, particularly for implantable and operating room devices needing testing in clean conditions. Test equipment must meet strict requirements for particulate generation and ESD protection to prevent PCBA contamination.

For sterilizable devices, the test strategy must consider performance verification pre- and post-sterilization, ensuring the process doesn’t affect PCBA functionality. This may require combining accelerated life testing with functional testing.

Supply Chain Collaboration Challenges Medical device manufacturing often involves multiple suppliers and contract manufacturers. Test strategies must be standardized across the supply chain to ensure consistent quality requirements.

Test data exchange becomes a key challenge, necessitating unified data formats and acceptance criteria to make results from different locations comparable. Cloud platforms can enable real-time data sharing and centralized analysis, enhancing supply chain quality transparency.

5. Implementation Roadmap and Best Practices

Four-Phase Implementation Path Successful test strategy implementation requires a systematic approach:

Phase 1: Requirements Analysis (1-2 weeks)

- Analyze product risk class and regulatory requirements.

- Assess PCBA complexity and production scale.

- Define quality objectives and key performance indicators.

Phase 2: Strategy Design (2-3 weeks)

- Select the test technology mix and hybrid strategy.

- Design test point layout and DFT rules.

- Establish test standards and acceptance criteria.

Phase 3: System Implementation (4-8 weeks)

- Configure test equipment and develop software.

- Establish data analysis and reporting systems.

- Validate test coverage and effectiveness.

Phase 4: Continuous Optimization (Ongoing)

- Monitor test data and defect patterns.

- Optimize test parameters and adjust strategy.

- Update test programs to accommodate design changes.

Common Pitfalls and Mitigation Strategies Common pitfalls in medical device test strategy implementation include:

- Over-Testing:Increases unnecessary cost and extends lead time. Solution: Determine critical test items based on risk analysis, avoiding perfectionist tendencies.

- Test Gaps:Coverage blanks between different methods lead to defect escapes. Solution: Perform gap analysis to ensure continuous test coverage.

- Data Silos:Isolated data from different test systems lacks correlation. Solution: Establish a unified data platform for integrated and correlated analysis.

6. Future Trends and Innovation Directions

Development of Intelligent Test Systems Test technology is moving towards intelligence and adaptability. Machine learning-based test systems can analyze historical data, predict potential failure modes, and adaptively adjust test parameters, improving efficiency and accuracy.

Digital Twin technology allows simulation of the test process in a virtual space, optimizing the test strategy upfront and reducing physical test iterations. For high-risk medical devices, this virtual validation can significantly reduce development risk.

Predictive Quality Analytics By integrating test data with production process data, advanced analytics systems can identify correlations between process parameters and final quality, enabling predictive quality control.

For example, analyzing the correlation between reflow soldering temperature profiles and ICT test results can optimize soldering parameters to prevent defects proactively, shifting quality focus from detection to prevention.

Flexible Test Platforms As medical devices trend towards personalization and customization, test platforms require greater flexibility. Modular test systems can be rapidly reconfigured for different products, meeting the needs of high-mix, low-volume production models.

Cloud-native test platforms enable elastic allocation of test resources and remote deployment of test programs, supporting quality consistency in distributed manufacturing models.

Conclusion

In medical electronics manufacturing, selecting a test strategy is an art of balance, not a simple technical decision. A successful strategy requires comprehensive consideration of product risk, production scale, technical feasibility, and economics. ICT, Flying Probe, and Functional Testing each have their strengths, and a hybrid strategy often yields the best results.

As medical devices evolve towards greater intelligence and personalization, test technologies must correspondingly advance. Future test strategies will become more intelligent, flexible, and predictive, providing stronger safeguards for the safety and efficacy of medical devices.