Introduction:

In new energy vehicles, aerospace and other high-precision fields, electronic components welding of small defects may cause significant risks. Vacuum reflow soldering technology with its unique vacuum environment welding characteristics, is becoming the PCBA foundry industry to break through the quality bottleneck of the ultimate solution.TORTAI as the first in the Pearl River Delta with the same level of scale of highly reliable PCBA electronic assembly manufacturing service providers, we use this article will be the depth of analysis of the core advantages of this revolutionary technology and application scenarios.

1、The principle of vacuum reflow soldering technology revealed

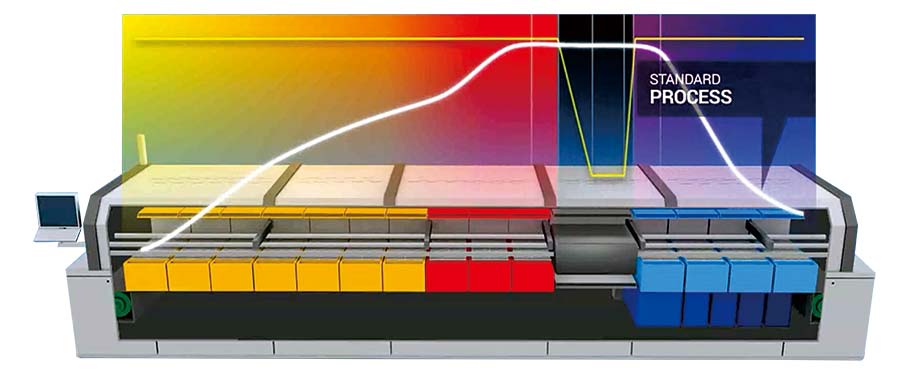

1.1 Vacuum environment how to subvert the traditional welding

Through the precision vacuum pump will be welding chamber air pressure down to 100-500 mT (about 0.013-0.065kPa), in a low-pressure environment to achieve solder melting. This process can effectively eliminate more than 97% of the soldering bubbles, and control the void rate of the solder joints within 0.5%, which far exceeds the standard of traditional reflow soldering process.

1.2 Three-stage precision control process

Vacuum pumping stage: 30 seconds to establish a stable vacuum environment gradient heating welding: precise control of 5-8 ℃ / s heating rate rapid cooling curing: nitrogen-assisted cooling system to achieve 10 ℃ / s cooling rate

2、The four core advantages of vacuum reflow soldering

2.1 Military grade welding reliability

Through the elimination of soldering bubbles, the product pass rate increased to 99.98%, especially suitable for aerospace electronic equipment and other extreme environmental application scenarios.

2.2 Material compatibility breakthrough

Supports a full range of materials from traditional Sn63Pb37 solder to the latest SnAgCu lead-free solder, compatible with ROHS and other international environmental standards.

2.3 Thermally sensitive component protection

Precise temperature control under vacuum environment (±1℃ fluctuation) makes BGA, QFN and other precision packaging components welding yield increased by 40%.

2.4 Comprehensive cost reduction

Compared with the traditional process, the rework rate decreased by 60%, the equipment crop rate increased to 85%, the return on investment of up to 230% over a three-year period.

3、The vacuum reflow soldering technology application scenarios map

| Industry Sectors | Typical Application | Benefits Enhancement |

| New Energy Vehicle | Electronic Control Unit (ECU), BMS system | 3 Times Higher Vibration Resistance |

| Medical Equipment | Implantable Medical Chips | 50 Per Cent Longer Product Life |

| 5G Communications | Millimetre-wave radio frequency modules | Signal loss reduced by 18dB |

| Industry 4.0 | Smart Sensor Nodes | Failure interval extended to 50,000 hours |

4、The implementation of vacuum reflow soldering practice path of enterprises

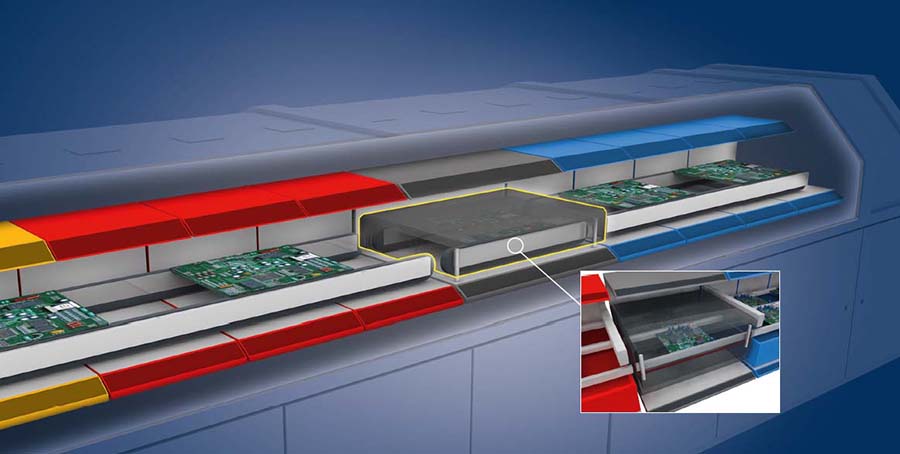

4.1 equipment selection guide

Recommended configuration parameters:

Vacuum: ≤ 5 × 10-²mbar

Heating zone: more than 10 temperature zone

Cooling rate: ≥ 6 ℃ / s

4.2 Talent cultivation system

It is recommended to establish a three-level training mechanism:

Basic operation certification (50 hours)

Process optimisation special training (30 hours)

Advanced fault diagnosis course (20 hours)

4.3 Customer value transfer strategy

Establishment of welding quality data board

Provide X-ray solder joint inspection report

Produce process comparison video material

5、Industry Development Trend Outlook

5.1 Intelligent upgrade direction

IOT remote monitoring system AI welding joint defect automatic detection digital twin process simulation platform

5.2 Market Growth Forecast

According to Global Market Insights data, the vacuum reflow soldering equipment market will grow at a CAGR of 11.2% in 2023-2030, and the proportion of demand in the field of new energy automotive electronics will exceed 35%.

Conclusion:

Mastering vacuum reflow soldering technology has become a necessary capability for high-end PCBA foundry manufacturers. Through the process analysis and implementation guide in this article, companies can quickly build a differentiated competitive advantage.

Please contact us immediately to solve your soldering void rate <3% of small and medium volume order manufacturing challenges, unlock your product quality upgrade programme!